Image courtesy of Columbia Forest Products.

If you took a giant pencil sharpener, sharpened a giant pencil, and then glued all the shavings together, you would have a plywood structural panel. Plywood is made of thin sheets of wood veneer laminated together in a hot press. Most people at some point have seen plywood used in construction and are familiar with the way it looks, however they are less used to seeing plywood’s less-expensive alternative, oriented strand board (OSB). OSB is another form of structural panel, made from thin wood strands, mixed with wax and adhesive and then hot pressed.

Image courtesy of the International Association of Certified Home Inspectors.

In general, OSB is less expensive than plywood by about $3 to $5 per panel. For example, if you build a 2400 square foot home and use OSB instead of plywood (for the sheathing, subfloor, and roof decking), you will save about $700 off of the materials cost. If you’re wondering why OSB costs less, the answer is producing this type of structural panel requires less use of older trees. Because OSB is made from smaller trees, which are often farmed, old growth timber is not needed for its production (as it is for the production of plywood).

Image courtesy of The Family Handyman.

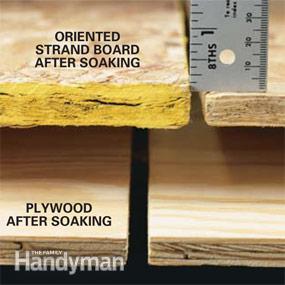

There is a price though, for using a less expensive material. Although OSB has a number of advantages over plywood (larger panels and greater shear strength), it is often its low tolerance of moisture that causes builders of high end homes to favor plywood instead. If OSB gets exposed to a significant amount of moisture or water, the edges can expand by up to 15 percent, affecting other architectural elements such as the roof shingles or the flooring. On the other hand, if plywood gets wet, it expands evenly, dries faster than OSB and quickly shirks down to its original size.

If you are thinking of using OSB for your next project to cut costs, make sure it is stored in a dry area, installed properly, and ventilated adequately. This should help prevent the panel edges swelling due to moisture.

Image sources:

1) Columbia Forest Products

2) International Association of Certified Home Inspectors

3) The Family Handyman