Music is liquid architecture; architecture is frozen music.

– Johann Wolfgang von Goethe (some 18th century old guy with a flair for the dramatic).

That seems about right to me.

What good ole Wolfie didn’t get around to mentioning was how the architectural process can sometimes resemble that old saying about making sausage. Now, this blog is not about design or construction documents (CD’s), specifically. That would be the creative, paint-a-picture, kumbaya phase. This is about the foundation for all else: materials. Regrettably, this specification often takes place after the CD’s are well underway.

Sometimes architectural materials specifications can be a simple thing to do. Building components that are basic and/or typical throughout an architect’s body of work are most often re-used in similar projects. As a result, their specification is straightforward, just like preparing a birthday cake is straightforward. Milk, flour, sugar, and a leavening agent are all ingredients for making a birthday cake, or almost any cake. Those ingredients are like specifications. The way the mix is created is also like a building’s specifications. Accordingly, specifications can have important directions to follow, which result in a masterpiece of cake art in baking, and a masterpiece of a building in architecture. Architecture is an art, too, as we have heard from Goethe, at least when the directions are followed. Otherwise, it could turn into sausage.

About those directions: my sister, on her seventh birthday, wanted a fancy birthday cake. My father contacted a baker who happened to be living in a nearby country. He spoke and understood the English language poorly but understood enough to get the “cake” part of the message. When dear old dad went to pick it up and took it home to my sister, we all found out that the cake, lovely as it was with all that sweet, colorful icing, was pretty disgusting. The entire insides, the cake part, was made from a tasteless corn meal. Imagine taking a taste and expecting something else. Anyway, it was a good life lesson: clear instruction matters. The building industry knows this and strongly supports concise specifications for construction products.

Specifications are employed within the body of documents to supplement the construction document. In the first place, a separate document having all of the necessary approvals, references, and procedures according the manufacturer’s instructions can better be presented in a consistent format that the Construction Specifications Institute (CSI) has used for decades. It has its roots in the MasterFormat outline that was created in 1963. Over the next decades, it was reviewed and refined and became what one sees today.

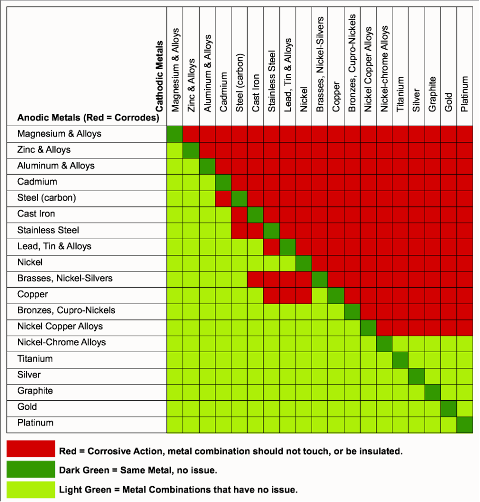

For example, if the drawings state that an exotic species of wood is intended for use as a feature of the casework, then oriented strand board or even soft pine would be a poor substitution. Similarly, some materials just do not play nice with others. As can be seen in the chart below, copper does not play nice with other metals, and the same can be said about brass (and others, like nickel-silver, depending on the adjacent compositions).

Roofing materials also are subject to care in writing specifications. These days, roof membranes can be a variety of materials; EPDM, TPO, and the old workhorse, bitumen products, all are effective roof coverings and each has distinct advantages. The accessory materials, glues, pitch-pockets, and reinforcements, etc. must be of the same, or compatible, material as the intended roof covering. (Stay away from EPDM accessory materials on a TPO or a bitumen based application, for example.)

Specifications abound with these little challenges.

The first skill for a specifier, then, is a good working knowledge of materials.

These relationships exist in other ways in specifications, too. The specifier must be aware of potential conflicts.

There are fundamentally three types of specifications: outline specifications, sheet specifications, and three-part specifications. The first, Outline Specs, is an itemized list, using brief, concise statements, which address significant materials, systems, and equipment and their criteria and levels of quality. Three part specifications are specifications that go into great detail about the materials, manufacturers, and related issues. There are a LOT of links between different Sections in a specification of this type, and far more that can be summarized through their sometimes-exhausting relationships with other sections.

That fancy exotic wood mentioned earlier could be living in the Division 6 for Finish Carpentry, Bu it will also be referenced in other divisions, such as cabinetry, door finishes, artwork, and those need to be organized and cross-referenced.

Sheet specifications lie right between three-part and outline specifications. Used particularly on projects of minimal scope or perhaps brought to the project by an owner or contractor because the project represents a chain of construction projects with identical or very similar attributes. For example: A fast-food chain restaurant may look different from others, but on the inside it’s almost always the same; same kitchen, same counter-queue design, booths, etc. It is a brand, and so there must be a consistency in materials and such to reflect that brand.

Specifications are an indispensable resource in construction and there are several ways it can accomplish that goal. Correctly compiled specifications can make a profound impact on budget and consistency of a clients preferences.

Work with EVstudio on your next project to make sure you’re partnered with a firm that will tend to these details from the jump to keep things moving smoothly. Let us know how we can help!