Construction 3D Printing (C3DP): Revolutionizing Building Construction

Construction 3D Printing (C3DP) is transforming the building industry, offering new ways to construct structures faster, with reduced waste and cost. This article covers what C3DP is, how it works, its applications, benefits, drawbacks, and a future outlook for the technology. We’ll also cover key manufacturers in the industry and how to locate C3DP services in your area.

What is Construction 3D Printing?

Construction 3D Printing (C3DP) involves using 3D printing technology to construct buildings and components layer by layer, using various materials like concrete, polymers, and composite mixes. With advanced computer-aided design (CAD) models, C3DP enables automated construction, bypassing traditional methods like concrete formwork and bricklaying. While still developing, C3DP technology holds significant promise in addressing housing shortages and sustainability goals.

How C3DP Works

C3DP works through a robotic arm or gantry system equipped with a nozzle, which extrudes a building material layer by layer according to a CAD model. Here’s how the process works:

- CAD Model Creation: Engineers design a 3D digital model of the building or component.

- Slicing the Model: The model is “sliced” into layers, providing the printer with a step-by-step guide.

- Material Extrusion: The printer extrudes concrete or composite material layer by layer, solidifying as it’s laid down.

- Automated Build: The printer follows programmed coordinates, creating walls, floors, and even complex shapes autonomously.

With materials such as quick-drying concrete, C3DP allows for continuous printing, sometimes completing a structure in days instead of months.

Applications of C3DP in Construction

Construction 3D Printing is used in various applications across the construction sector, including:

- Residential Homes: C3DP can construct affordable, durable homes in days, reducing the labor and costs associated with traditional methods.

- Commercial Structures: Offices, retail buildings, and warehouses benefit from C3DP due to its speed and reduced material costs.

- Disaster Relief Housing: C3DP enables the quick construction of shelters after natural disasters, providing essential housing where it’s needed most.

- Bridges and Public Infrastructure: Printed bridges, benches, and other infrastructure show C3DP’s versatility beyond buildings.

- Component Manufacturing: C3DP also produces architectural elements like decorative facades, panels, and complex geometries not feasible with conventional construction.

Pros and Cons of Construction 3D Printing

Pros:

- Speed and Efficiency: C3DP shortens construction timeframes significantly, sometimes completing builds in a fraction of traditional times.

- Reduced Labor Costs: By automating processes, C3DP reduces reliance on manual labor, lowering project costs.

- Material Efficiency: Precise layering and automated control reduce waste, making C3DP more environmentally friendly.

- Design Flexibility: Complex shapes and customized designs are easily achieved without additional costs or complications.

- Sustainability: C3DP allows the use of sustainable materials, decreasing the overall environmental footprint of construction.

Cons:

- High Initial Investment: C3DP systems require significant upfront capital for equipment and setup.

- Material Limitations: Not all construction materials are suited for 3D printing, and achieving standard building codes with new materials can be challenging.

- Skill Requirements: Operating C3DP technology requires specialized training, limiting accessibility for all construction teams.

- Structural Limitations: Although evolving, C3DP currently has limitations in high-rise and complex building construction, primarily suited to simpler, low-rise structures.

Future Outlook for C3DP Technology

The future of C3DP looks promising as technology advances in efficiency, material options, and scalability. Researchers are exploring the use of eco-friendly materials, like recycled plastics and bio-based composites, to enhance sustainability further. More governments and institutions are recognizing C3DP’s potential in affordable housing and disaster relief, leading to greater regulatory support and funding.

Technological innovations will also expand C3DP’s applications to more complex structures, potentially including multi-story buildings and high-rise towers. This evolution could result in lower construction costs, faster project delivery, and improved environmental sustainability on a global scale.

Manufacturers of C3DP Systems

Several companies are leading in developing and manufacturing C3DP systems:

- Apis Cor: Known for constructing 3D-printed homes, Apis Cor is a pioneer in concrete-based 3D printing.

- ICON: Focused on affordable housing, ICON uses its Vulcan printer to produce durable, low-cost homes.

- Winsun: Winsun specializes in commercial-scale C3DP and has printed office buildings, residential structures, and various architectural components.

- CyBe Construction: Based in the Netherlands, CyBe Construction provides a range of mobile 3D concrete printers for diverse applications.

Finding C3DP Technology Near You

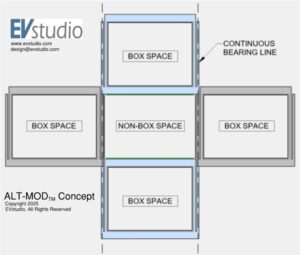

To locate C3DP services or providers, start by checking with established manufacturers such as ICON or Apis Cor, which often list their service areas on their websites. Additionally, design firms like EVstudio and construction firms specializing in modern building technology may offer C3DP solutions or partnerships with C3DP companies. Universities and research institutions working in digital fabrication are another good resource for information and collaboration opportunities.

References: