Laminated Veneer Lumber (LVL) is a manufactured structural wood product that is utilized when the strength requirements of a timber beam exceed that of your typical sawn lumber beam. LVLs are produced by taking wafer thin slices of wood and sandwiching them together (see photo below). Each slice of wood is oriented with the grain perpendicular to the slice next to it. The “sandwich” is then held together with a high strength epoxy. The result is a timber framing member that is not only superior in strength, but can be purchased in lengths of up to sixty feet while staying straight as an arrow. Finding a 2×8 longer than ten feet long at your local lumber yard that isn’t warped would be a difficult task.

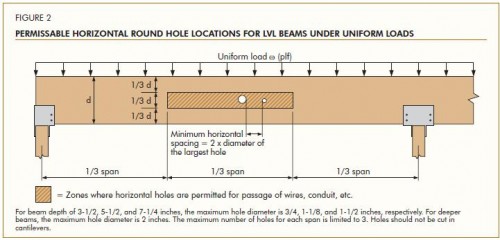

In any construction project, especially new additions to homes or commercial buildings, there is a limited amount of space to run utilities such as electrical wires or water pipes. Sometimes the only available option is to port these utilities through the beam. As with all timber construction, a square hole should never be cut into an LVL beam. Square cuts develop stress concentrations and are prone to splitting. Round (drilled) holes are preferred because they allow stresses to develop “more smoothly” around the opening. As a beam is loaded, stresses concentrate in different areas. Knowing this, the APA (The Engineered Wood Association) has created the illustration shown below as a field guide to the most desirable places drill holes in LVL beams. Please keep in mind that it is always safer to consult your licensed structural engineer when modifying any load bearing member.

The EWS G535A is a free publication from the APA which goes into much greater detail than presented here. The APA’s website is a great resource for builders, engineers, architects and home owners who are looking for information on manufactured lumber products.

1 thought on “Field Drilling Holes in Laminated Veneer Lumber (LVL) Beams”

Then how are the metal joints (from the posts) drilled to the LVL?

Comments are closed.