Foundation Waterproofing Methods: A Guide to Effective Solutions

Foundation waterproofing is essential for protecting buildings from moisture damage and structural deterioration. Engineers and builders use different waterproofing methods based on site conditions, soil composition, and project requirements. Proper waterproofing prevents water intrusion, reduces maintenance costs, and extends a building’s lifespan.

Positive, Negative, and Blind-Side Waterproofing

Foundation waterproofing systems fall into three categories: positive-side, negative-side, and blind-side. Each approach serves different conditions and project constraints.

Positive-Side Waterproofing

Positive-side waterproofing applies a protective barrier to the exterior surface of a foundation wall. It prevents water from reaching the structure and directs moisture away. This method is the most effective because it stops water before it enters the building. However, it requires exterior access, which can be challenging in existing structures.

Negative-Side Waterproofing

Negative-side waterproofing applies a barrier to the interior surface of a foundation wall. It does not prevent water infiltration but manages moisture that has already entered. This method is useful for repairing existing foundations but is less effective at preventing long-term damage.

Blind-Side Waterproofing

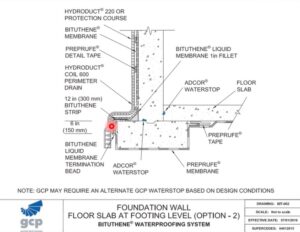

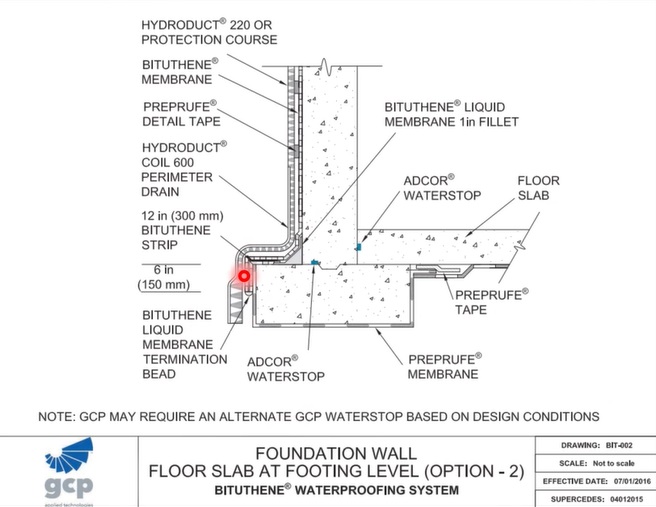

Blind-side waterproofing is used in below-grade construction where access to the exterior is impossible. Builders apply the waterproofing system before pouring the foundation against a soil retention system, such as sheet piles or shoring walls. This method is common in urban settings and sites with limited excavation space.

Types of Foundation Waterproofing Methods

Liquid-Applied Waterproofing

Liquid-applied waterproofing consists of elastomeric coatings that form a seamless, flexible membrane. Workers spray or roll the material onto the foundation surface.

Pros:

- Forms a continuous barrier with no seams

- Adapts to complex foundation shapes

- Provides excellent adhesion to concrete

Cons:

- Requires a clean, dry surface for application

- Can be affected by weather during installation

- Needs skilled labor for uniform coverage

Sheet Membrane Waterproofing

Sheet membranes are pre-manufactured waterproofing layers that workers adhere to foundation surfaces. These membranes typically consist of rubberized asphalt, PVC, or thermoplastic materials.

Pros:

- Offers consistent thickness and quality control

- Provides high puncture resistance

- Works well in various soil conditions

Cons:

- Requires careful installation to prevent gaps or seams

- Can be difficult to install on irregular surfaces

- May need additional protection against damage during backfilling

Bentonite Clay Waterproofing

Bentonite waterproofing consists of natural clay panels or sheets that expand when exposed to water, forming a waterproof barrier. This system is often used for blind-side applications.

Pros:

- Self-sealing properties fill small cracks and voids

- Works well in blind-side applications

- Environmentally friendly and long-lasting

Cons:

- Requires confinement to remain effective

- Loses effectiveness if allowed to dry before backfilling

- Can be difficult to install in extremely wet conditions

The Role of the Geotechnical Engineer

The geotechnical engineer plays a crucial role in foundation waterproofing design. They assess site conditions, soil composition, and groundwater levels to recommend the best waterproofing system. Engineers must also specify drainage solutions, such as perforated pipes, gravel backfill, and drainage boards, to manage water flow around the foundation.

Proper coordination between geotechnical engineers, structural engineers, and contractors ensures a waterproofing system meets performance and durability requirements. Engineers must also consider local building codes and industry standards when designing waterproofing and drainage solutions.

Professional Organizations for Waterproofing Professionals

For additional resources, industry standards, and best practices, professionals can refer to these organizations:

- International Concrete Repair Institute (ICRI): https://www.icri.org

- National Waterproofing Supply Association (NWSA): https://www.nwsaonline.org

- American Concrete Institute (ACI): https://www.concrete.org

- Building Enclosure Council (BEC): https://www.nibs.org/bec

By selecting the right waterproofing method and ensuring proper installation, engineers and builders can protect structures from water damage and extend their lifespan.