Engineers, homeowners, and contractors will confuse floor performance with structural integrity. A structurally sound floor may not perform as well as a homeowner wants it to. Wooden I-joists, the most common type of floor system used in residential construction, can be designed and built in different ways to improve performance while maintaining structural integrity. Quality floor design has two main factors: deflection criteria and manufacturer floor rating. Although both refer to the physical behavior of the joists, deflection is the only engineering property that can be calculated.

Background

Wooden I-joists are made of top and bottom flanges joined together with webs. The flange material is typically laminated veneer lumber or sawn lumber, and the web is made with plywood or OSB. Some popular I-joist providers in North America are Weyerhaeuser and Boise Cascade.

Performance vs. Deflection

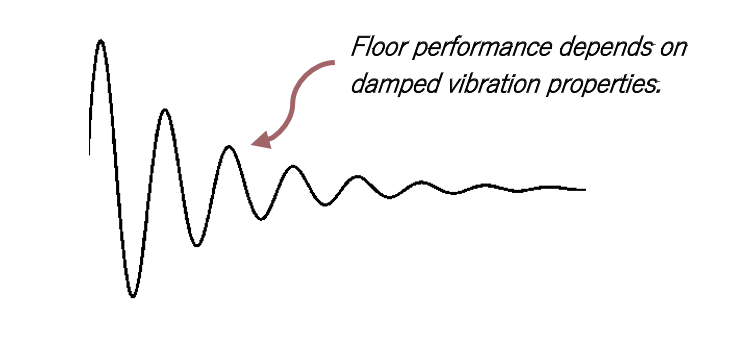

Vibrations reported as bouncy, squeaky floors are common in a system that “performs poorly”. This is a subjective parameter in residential construction. The assembly system of a floor (which includes nailing to the subfloor, bridging, and ceilings) affects the stiffness of a floor, which vibrations depend on.

On the other hand, deflection is the movement of a beam from its original position due to the applied forces. This is a static property, whereas performance is dynamic.

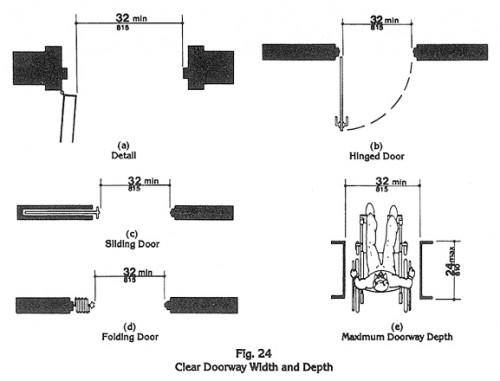

The International Residential Code (IRC) prescribes deflection limits for members under live loads and total loads (people and furniture are live loads, while the self-weight of the structure is dead load.) However, these limits are not related to performance. Frequency, amplitude, and damping are some physical dynamic properties.

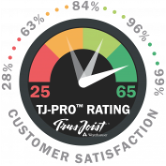

Weyerhaeuser developed the TJ-PROTM Rating system, based on subjective input from customers on 1000 floors over several years. This scale goes from 25 to 65, 45 being the rating at which 84% of people will find floor performance “good” or better.

Typically, production builders will aim for a rating of 40, whereas for custom homes this is usually higher.

Mitigating Vibration

Builders and engineers should be aware that the IRC’s minimum deflection criteria might not result in homeowner satisfaction. The following are best industry practices for a well-performing floor system:

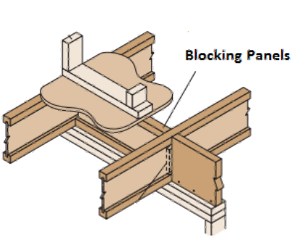

- Provide details for connections and blocking when expecting large deflections. This requires a bit of engineering judgement.

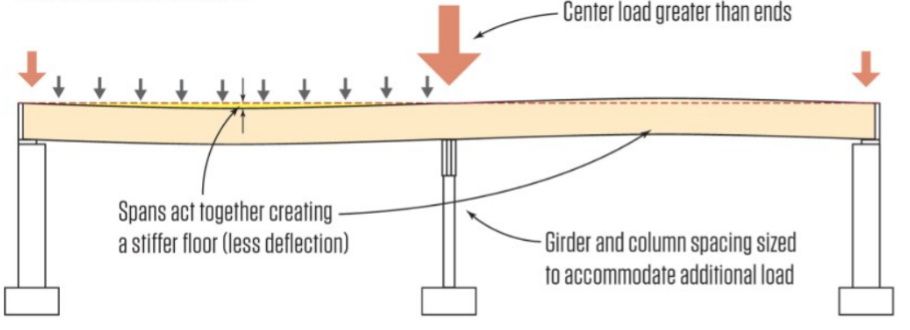

- Go beyond code minimum and design joists with deeper sections, reduced on-center spacing, and shorter spans. Call-out continuous spans, instead of many single-span joists.

- Set floor performance expectations with your client and/or owner. This will save all parties time and money throughout the project.

- Training framers on construction techniques that adhere to floor manufacturer specifications is a worthy long-term investment.

- Consider a higher performance rating if many customers are expressing dissatisfaction about their floor system.

Takeaway

Homeowners should be aware that floor vibrations might not compromise a structure. Engineers and contractors can set expectations on floor rating, and adjust construction plans as needed for a better performing structural system.