EVstudio is excited to be featured in the Modular Advantage Magazine (March/April 2025 edition).

Our project Architect, Alex Walz and Founding Principal, Dean Dalvit speak on the opportunities for innovation in modular offsite construction.

“The construction industry is undergoing a seismic shift as Fully Volumetric Modular Offsite Construction takes center stage. This innovative approach addresses challenges like affordability, efficiency, and sustainability while opening doors to groundbreaking advancements. To realize its full potential, an experienced, interdisciplinary team is crucial for successfully delivering state of the art Modular projects. Tremendous opportunities exist for innovation across architecture, structural engineering, and mechanical and electrical systems. Pioneering A/E firms are leading the way.”

Architectural Innovations: Beautiful Buildings Without Compromise

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Advanced Module Geometry and Configurations

Experienced architects utilize cutting-edge tools like Building Information Modeling (BIM) and design tools augmented with Artificial Intelligence (AI) to design unique modular geometries. Today’s modules can feature angled walls, curved surfaces, and staggered configurations that achieve dynamic forms and creative façades. For example, staggered modules can produce cantilevered elements and shifts in the building facade, while innovative layouts create seamless architectural flow. Collaboration among seasoned professionals in modular design ensures these designs align with manufacturing and assembly capabilities.

Innovative Materials and Products

Material advancements are redefining what’s possible in Modular Offsite Construction. Lightweight yet durable options like cross-laminated timber (CLT) and high-performance lightweight concrete enhance design flexibility. Ultra-slim insulation panels and panelized façade systems maximize interior space without compromising thermal performance. Sheathing products with integrated insulation and waterproofing reduce construction time and speed factory production. These innovations enable architects to create striking, sustainable structures that rival traditionally built projects.

Blending Aesthetics and Functionality

Customizable designs allow modular buildings to integrate seamlessly into their surroundings and even stand out as architectural landmarks. Architects working with modular experienced engineers ensure that every detail enhances both form and function. By combining design expertise with state-of-the-art tools, experienced modular designers deliver projects that meet the highest aesthetic and functional standards.

Structural Engineering Advancements: Simplifying Processes and Enhancing Durability

Structural engineering innovations are essential to the success of Modular Offsite Construction. With modular experienced engineers leading the way, these advancements simplify factory and field work while ensuring robust and resilient buildings.

Streamlining Factory and Field Work

Structural Engineers design modular frames using high-strength materials, such as steel and engineered lumber, to optimize manufacturing and assembly. Pre-installed components, like shear walls and bolted plate connectors, reduce the need for complex on-site work. These solutions accelerate timelines while improving precision and quality control.

Designing for Strength and Resilience

Transporting and assembling modules requires designs that prioritize durability. Structural Engineers develop advanced connection systems that ensure integrity during transport and installation. By incorporating seismic and wind-resistant features, they make modular buildings suitable for diverse climates and geographic locations. Experienced teams bring a deep understanding of these challenges, ensuring every project meets rigorous safety standards.

Advanced Technologies in Mechanical and Electrical Systems

Mechanical and Electrical Engineering innovations are transforming modular construction by delivering purpose-built systems that enhance energy efficiency, occupant comfort, and sustainability. With seasoned professionals driving these advancements, modular buildings are achieving industry leading performance standards.

Purpose-Built MEP Systems

MEP systems designed specifically for modular buildings simplify installation and improve reliability. Compact HVAC units fit within tighter spaces, while pre-wired electrical systems and plumbing assemblies intentionally designed for modular minimize on-site labor. These systems are tested in the factory, ensuring they perform as intended once installed.

Optimizing Energy Performance

Advanced technologies like smart HVAC systems and LED lighting with integrated controls optimize energy use. Renewable energy solutions, such as pre-installed solar panels and battery storage, further enhance building sustainability. These systems provide a level of performance and efficiency tailored to modular construction’s unique needs.

Integrated Collaboration Across Disciplines

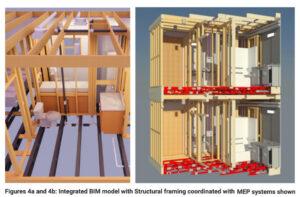

Close collaboration between Architects, Structural Engineers, and MEP Engineers ensures seamless integration of all systems with other building components. For instance, engineers can design floor systems with built-in channels for mechanical and electrical systems, reducing the need for additional coordination. Integrated Architecture and Engineering teams with expertise in modular design excel in fostering this interdisciplinary teamwork, which is vital for Modular Offsite Construction success.

EVstudio’s Role in Modular Innovation

EVstudio is an integrated Architecture and Engineering firm with multiple offices and staff across the country. Leveraging decades of expertise in architecture and engineering, EVstudio pushes the boundaries of what is possible in all market sectors. Within EVstudio, a purpose built team of specialists in Design for Offsite Construction known as the EVolution Studio focuses exclusively on advancing building technologies for Offsite Construction. EVstudio supports Manufacturers, Owners and General Contractors alike and ensures all stakeholder needs are met.

Integrated Design Approach

EVstudio employs an integrated design approach that brings together in-house Architects, Structural Engineers, and MEP Engineers all within the same Studio from project inception. This collaboration ensures that every aspect of the design is optimized for modular construction. By using advanced tools like BIM and parametric modeling with AI augmented capability coupled with good old fashioned human know-how and experience, EVstudio delivers designs that balance aesthetics, functionality, and efficiency.

Collaborating with NREL for High-Performance Systems

The National Renewable Energy Laboratory (NREL), based in Golden Colorado, focuses research on integrating renewable energy technologies into modular construction. The lab’s work includes energy-efficient heat pumps and other advanced systems as well as materials for improved insulation and air-sealing. Through its collaboration with NREL, EVstudio is at the forefront of implementing these innovations in real-world projects, setting new standards for sustainability in Modular Offsite Construction.

Pioneering Reversible Design™

EVstudio has introduced Reversible Design™, a groundbreaking proprietary system of A/E building technologies that enables buildings to be deconstructed and relocated without compromising aesthetics or function. Reversible Buildings™ use modular components designed for easy disassembly, promoting adaptability and reducing waste while also providing substantial financial and risk mitigation benefits to Owners and Developers. This innovative approach exemplifies EVstudio’s commitment to transforming the construction industry.

Conclusion

Modular Offsite Construction offers tremendous opportunities for innovation across Architecture, Structural Engineering, and MEP Engineering. With modular experienced teams leading the way, modular buildings can achieve stunning aesthetics, exceptional performance, and unparalleled sustainability. EVstudio, through its integrated design approach and collaboration with NREL, exemplifies how expertise and innovation drive the modular industry forward. By introducing Reversible Design™, EVstudio is not only redefining modular construction but also challenging traditional notions of what buildings can be. Modular offsite construction is poised to revolutionize the industry, creating a future of efficient, sustainable, and adaptable buildings.