There’s a lot that you can come across when renovating an existing building. Unknown aspects and unforeseen as-built conditions can throw a monkey wrench in your plans. Even conditions that we are aware of can be difficult to deal with. We ran into one such example just a few months ago that led us to use reinforcing bar couplers.

A client wanted to add a new roof in between an existing building and an existing exterior roof structure. While there’s nothing special about creating a new steel-framed roof, the new structure needs to use existing members and foundations for support. The tricky part came after analyzing the existing foundations.

Analysis

We attempted to transfer the new loads in as uniform a fashion as practically as possible. The IEBC contains a provision which states that no modifications are required for an existing structure as long as you stay within 5% of a member’s current capacity. In this situation, we weren’t able to take advantage of the code. The new structure called for additional columns that would bear on existing pad footings. Our first task was to make sure that these footings could handle the additional load (especially considering that the new load would be eccentric).

Result

We determined the current design loading of the structure from all information at hand and cross-checked with current code criteria. Then, we used finite element analysis software to determine the new pressures that the footings would exert on the soil below. In some cases, the existing footings were adequate to handle the additional loading (alright!!). But, there were a couple of locations where they weren’t… :(. To resolve this, we decided to widen inadequate footings and thereby increase the bearing area.

Now, the goal here is to widen the footing in need and still make it behave as one unit. We didn’t feel comfortable simply drilling and epoxying new rebar into the existing footing and calling it a day. Post installed bars can transfer tension and shear quite well, but not necessarily bending moment. Because of this, we sought to find a solution where a true mechanical connection could be made between the new and old steel.

Approach

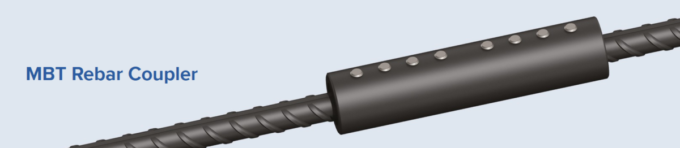

Our search led us to reinforcing bar couplers. Of the several types of couplers on the market, we chose the Ancon MBT model shown below (image 1).

“MBT Rebar Coupler.” Ancon, 2020, https://www.ancon.co.uk/products/reinforcing-bar-couplers/mbt-couplers.

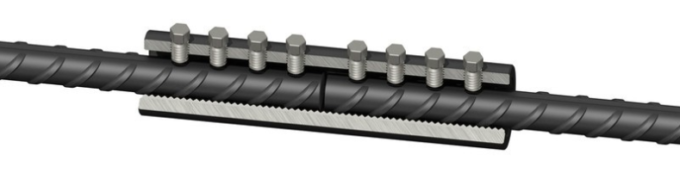

This model allows one to use the rebar as is without the need for any threading. The screw shown in the cross-section is embedded into the rebar at a pre-determined torque (image 2). At the same time, the saddles below the bar dig into the sides of both the bar and the coupler. This creates a solid connection between the new and existing bars and allows proper force transfer. Woohoo!!

Other Applications

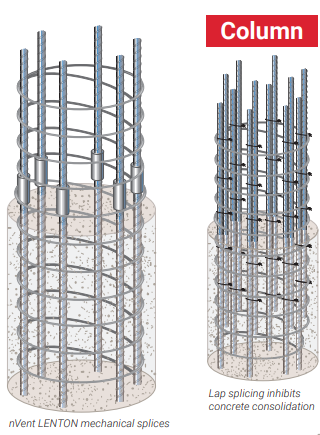

Expanding on this topic, reinforcing bar couplers such as this can replace rebar splices anywhere throughout a structure. They can eliminate bar overlap in sections of concrete members where code required bars become too densely spaced. A good example would be at concrete column bar splices as shown below (image 3). Another example would be for masonry walls that require short lifts. In the situation that requires a 4′ lift, three bars have a chance to overlap. That’s quite a bit of steel that couplers would help eliminate.

Whatever the case, whether it is new or existing construction, we at EV always strive to find the most efficient and cost-effective solutions to problems that one encounters in the design world. Please contact us with any questions you may have. If there is a solution, we’ll find it. Thanks for reading and if you would like to learn more feel free to email us.

Resources: