The Science Behind Structural Insulated Panels (SIPs) in Building Construction

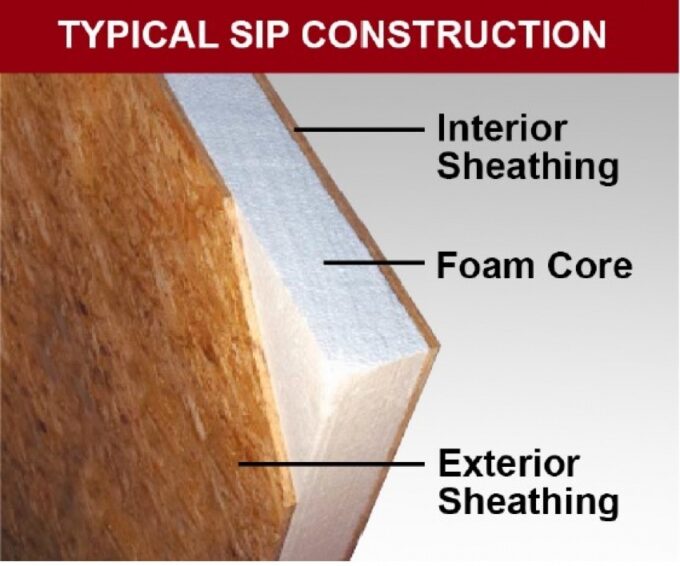

Structural Insulated Panels (SIPs) offer a modern, energy-efficient solution for building construction. These panels consist of an insulating foam core sandwiched between two structural facings, usually oriented strand board (OSB). SIPs provide excellent thermal performance, strength, and ease of installation. This article will explore the science behind SIPs construction, their ideal applications, advantages, disadvantages, and cost comparison to other construction methods.

What is SIPs Construction?

SIPs construction involves using prefabricated panels to create walls, floors, and roofs. Manufacturers bond an insulating foam core, typically expanded polystyrene (EPS) or polyurethane, between two OSB facings. These panels serve as both insulation and structural elements, reducing the need for traditional framing. Builders assemble SIPs on-site, connecting panels with splines, and securing them to the building’s foundation.

Ideal Project Types

SIPs construction works best for projects prioritizing energy efficiency and speed. Residential homes, schools, commercial buildings, and light industrial structures benefit from SIPs due to their high insulation values and quick assembly. SIPs are particularly suitable for energy-efficient homes and buildings aiming for certifications like LEED or Passive House.

Differences from Other Construction Methods

SIPs differ from traditional stick framing and other prefabricated methods in several ways. In stick framing, builders construct walls with individual studs, insulation, and sheathing, which requires more time and labor. SIPs, however, combine these elements into a single panel, speeding up construction. Unlike traditional insulation methods, SIPs offer continuous insulation without thermal bridging, enhancing energy efficiency.

Advantages of SIPs Construction

- Energy Efficiency: SIPs provide superior insulation, reducing energy costs and improving indoor comfort. Research shows that buildings with SIPs can achieve up to 50% energy savings compared to traditional construction (source: U.S. Department of Energy).

- Speed of Construction: Builders can assemble SIPs quickly, reducing construction time by up to 50% compared to stick framing. Prefabrication ensures consistent quality and reduces on-site labor.

- Strength and Durability: SIPs offer excellent strength-to-weight ratios and can withstand high wind loads, making them suitable for areas prone to severe weather.

- Sustainability: SIPs reduce material waste and can be made from environmentally friendly materials, contributing to sustainable building practices.

Disadvantages of SIPs Construction

- Initial Costs: SIPs may have higher upfront costs compared to traditional framing materials. However, these costs can be offset by energy savings over time.

- Design Limitations: While SIPs are versatile, they may not be suitable for projects requiring complex architectural details or curves. Custom shapes and sizes can increase costs and complicate the construction process. Additionally, special care must be taken anywhere fire rated assemblies are required.

- Moisture Sensitivity: SIPs must be properly sealed and protected from moisture to prevent mold and rot. Builders must pay close attention to sealing joints and openings.

Cost Comparison

SIPs construction typically has higher initial costs compared to traditional stick framing. However, these costs are often offset by reduced labor, faster construction, and long-term energy savings. According to the U.S. Department of Energy, buildings using SIPs can save up to 50% on energy costs over their lifespan, making them a cost-effective choice for energy-efficient construction.

Conclusion

Structural Insulated Panels provide an innovative, energy-efficient solution for modern building construction. Their ability to deliver superior insulation, strength, and quick assembly makes them ideal for residential, commercial, and light industrial projects. While SIPs may have higher initial costs and some design limitations, their advantages in energy efficiency and sustainability often outweigh these drawbacks. Understanding the science behind SIPs construction enables builders and developers to make informed decisions that align with their project goals and budget. If you are considering SIPs for your next project, reach out to our team of A/E experts at EVstudio and we would be happy to help!

References

- U.S. Department of Energy. (n.d.). Benefits of Structural Insulated Panels. Retrieved from Energy.gov

- Structural Insulated Panel Association. (2023). SIPs in Modern Construction: A Comprehensive Guide. Retrieved from SIPA

By leveraging the benefits of SIPs, you can create buildings that are not only cost-effective but also environmentally friendly and energy-efficient.