How do I determine when to use PVC and ABS Plumbing Piping?

Introduction to PVC and ABS Plumbing Piping

PVC (Polyvinyl Chloride) and ABS (Acrylonitrile Butadiene Styrene) are popular choices for plumbing in commercial and residential buildings. Moreover, both materials offer advantages and are addressed in the regulatory plumbing codes.

Differences Between PVC and ABS

Material Composition

- PVC: White plastic made from polyvinyl chloride.

- ABS: Black plastic made from acrylonitrile, butadiene, and styrene.

Flexibility and Strength

- PVC:

- More rigid

- Slightly more expensive

- Quieter (thicker wall)

- Therefore typically used in all building types including Commercial and Multifamily

- ABS:

- More flexible

- Less expensive

- Noisier (thinner wall)

- Therefore typically used in Residential only

Installation

- PVC: Requires a two-step process with primer and cement.

- ABS: Requires a one-step process with special cement.

IBC Regulations for plumbing piping

The International Building Code (IBC) outlines the use and installation of plumbing piping to ensure safety and reliability.

Key IBC Sections for Plumbing Piping

- IBC Chapter 29: Addresses plumbing systems, including material requirements.

- IBC Chapter 7: Covers fire and smoke protection features affecting piping installations.

Evaluating Options with a Plumbing Engineering Team

Assessing Project Needs

An experienced plumbing engineering team evaluates the specific needs of the project. In addition, they consider factors like temperature, pressure, and building codes.

Ensuring Code Compliance

Professionals ensure that installations comply with IBC regulations. As a result, this avoids costly rework and ensures safety and efficiency.

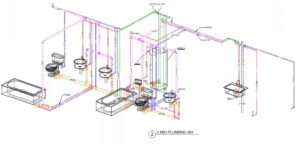

Example: Residential Use

In residential buildings, ABS is often used for drain, waste, and vent (DWV) systems. Therefore, its flexibility and quick one-step installation is well suited for home plumbing where temperature variations are minimal.

Example: Commercial Use

In commercial buildings, PVC is preferred for its durability and performance in low-temperature environments. Compliance with IBC Chapter 29 ensures proper installation and safety. Additionally, Compliance with IBC Chapter 7 ensures the system meets fire safety requirements.

To conclude, by consulting an experienced plumbing engineering team like our experts at EVstudio, you can choose the best material for your project and ensure compliance with code regulations.