The concrete that is used today typically consists of five materials; air, Portland cement, gravel and crushed stone, sand, and water. Roughly 10-15% of that mixture is cement. Cement is a very energy intensive product to create. The creation of cement requires approximately 6.5 million BTU’s of energy per ton. The cement industry is resonsible roughly 8% of the world’s CO2 emissions.

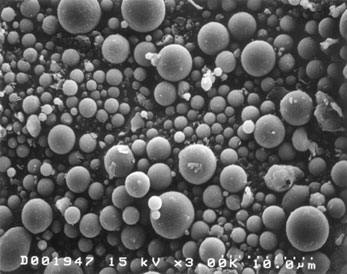

A great substitute for the cement in concrete is fly ash. Fly ash is a by-product of coal fired power plants. Instead of extracting a specific material and processing it, like the components of cement, fly ash comes directly from another process. Of the 60 million tons of fly ash produced as a side effect of energy production, roughly 70% finds its way into landfills.

Fly ash has cementing properties. Class ‘C’ fly ash as defined by ASTM C618 has the best cementing properties. There are actually two types of fly ash, ‘F’ and ‘C’. Class C has self-cementing properties while class F has little to no cementing value. Class C is generally the better choice for a cement substitute. There are some considerations such as finishing and curing time of mixes made with either of the two classes.

The American Concrete Institute has approved class F fly ash to replace 15-25% of cement in a typical mix and a 20-35% replacement percentage when using class C fly ash.

Since fly ash is a post industrial waste product, it can count towards the LEED certification of a building. It is also interesting to note that fly ash was used in the construction of the Hoover dam back in 1929.