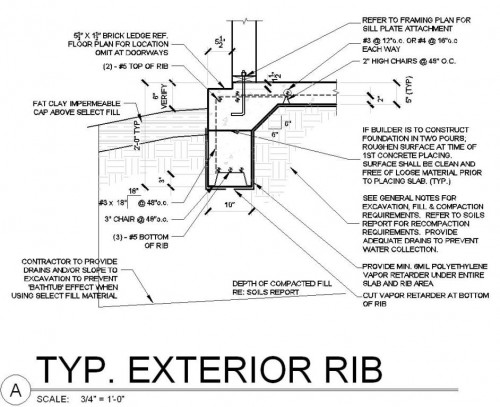

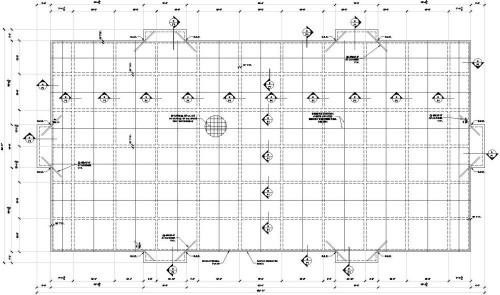

EVstudio Engineering just finished designing a typical slab-on-grade foundation for a 12,000 sq ft commercial building in Central Texas. Due to accessibility to plumbing below the slab the owner wanted to have a mildly reinforced slab in lieu of a post tension slab. Based on the geotechnical design parameters the foundation required 24″ deep ribs x 10″ wide. Fairly typical for a site that will be over-excavated and filled with suitable material reducing the risk of slab movement.

EVstudio then compared our design to the foundation design that the owner was provided by another engineer for the site next door with the same soil design parameters. We were able to reduce rib depth, rib width, slab thickness, and reinforcement of the ribs. Just by sharpening the pencil, EVstudio reduced concrete volume by 80 cubic yards and steel by 7,250lb. The contractor estimates savings of at least $11,650!

The material savings is based on a estimated cost of $80 per cubic yard for concrete and $0.70 per lb for steel.

If you are interested to see if EVstudio can save you money on your building please email jim@evstudio.us or call 303.670.7242.

4 thoughts on “Value Engineering of Slab-on-Grade Foundation”

James,

“Sharpening the Pencil” is NOT criminal. Providing under designed structures that do not meet code is.

When someone is to value engineer a structure it’s based on years of experience and knowledge of what works and doesn’t work to reduce materials and labor costs. However, all codes and accepted building standards should always be maintained. ALL loads are always accounted for, that’s code. Wind, seismic, lateral soil pressure, snow, snow drifting, occupancy live loads and dead loads are the basic forces the designer must include. No load is ignored for value engineering.

Couldn’t it be considered criminal to specify excessive building materials such as steel, concrete, wood at the owner’s expense? The owner is relying on the engineer and architect to provide a quality product built the easiest and most cost effective way.

There are factors of safety and reductions in actual material strengths that are used to prevent failures as long as the designer satisfies code. Why design for more, unless at the owner’s request or based on experience?

James,

Thanks for the comment, we always appreciate vigorous debate. Just as a note to other readers we have absolutely nothing to do with the builder that you are referring to and have never worked in Nevada. The residential slab type that you are describing is also very different from the commercial slab that we designed for this site in Texas and I can’t speak to your story.

That being said, there are certainly examples where engineers have underdesigned as well as overdesigned. What is important is that we design all of our structure to meet both code and the expected level of performance for the project. Our clients gain nothing through excessive and costly over design.

In the example what we had found is that the previous engineer hadn’t been designing efficiently, instead they were simply rounding up to an extent that was costing the client and performing no better than our design. Because we took the time to do the math and run the calculations we were able to provide a value to our client.

On a side note, EVstudio has also been called into projects to help evaluate why designs by other architects and engineers have failed and to provide remedies. Design that is not up to code and performance standards does happen and we step in to provide ways to fix it. It is very important to choose the right design team.

Jim FYI: A once, very prominent Builder of premiere homes in SouthWest Reno applied cost cutting, value engineering by reducing the thickness of the slab – reducing the width of the perimeter footings (ribs) , and also by substituting “useless” , micro -synthetic fibers ( fibermesh) for steel rebar.

Similar to what you stated above, the cost of the project was reduced by several thousand dollars by reducing the amount of concrete and the cost of the steel, but the slabs of these homes have now cracked and so have the perimeter footings !

In sum, “sharpening one’s pencil” and cutting the cost of the project – by so-called value-engineering – which does not take into consideration the lateral (horizontal) (wind and seismic ) loads on the slab- on -grade which causes bending moments that crack an un-reinforced slab and under-reinforced perimeter footings is not only assine but also criminal.

Pingback: Free Review of Structural Plans for Value Engineering | EVstudio Architecture, Engineering & Planning | Blog | Denver & Evergreen | Colorado & Texas Architect

Comments are closed.