Not all fire resistance treatments for wood are the same. Over the past few months, I have been learning about the differences between treatment strategies for wood. The following breakdown is a brief synopsis of those differences:

Intumescent Paint

Intumescent paint is a treatment applied to the outside surface of a variety of materials including wood and steel framing. When the coating comes in contact with high temperatures, it expands, creating a foam-like layer on the material that is a poor conductor of heat. Intumescent paint products are typically not inexpensive, but are a great option for fireproofing areas that would be difficult for application or use of other fire resistive treatments. The duration of the ability of the intumescent paint to resist burning or protection of the material it is coating typically depends on the thickness of the layer applied. Typical thicknesses for 1 and 2 hour fire ratings are between 30 mil and 60 mil applications.

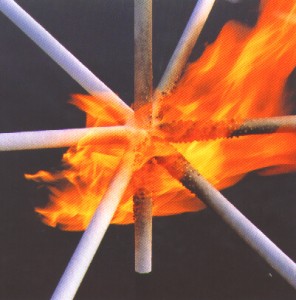

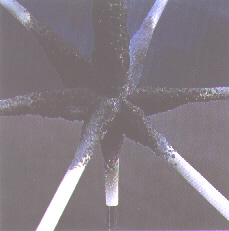

Intumescent paint while being burned and after burning

Note: Intumescent paint does not burn itself! The first picture is of the paint being burned with a torch.

Surface Treatments

A number of products on the market use a spray or painted treatment that chemically slows flame spread or decreases the amount of smoke that will be produced if the product does burn, but does not offer much protection if the initial layer is penetrated or compromised. These products differ from the intumescent paint in that they do not create any protective heat barrier. Some building departments will accept this treatment for wood framing, but some jurisdictions, such as Denver, do not accept surface treated wood products as being “fire resistive” as the layer is not “impregnated” into the material and is compromised when the wood is cut or altered after the application of the surface treatment. These products are decent at reducing the rate of flame spread and are the least expensive option for fire resistive treatment, but do not offer too much structural protection; once wood treated with this option starts burning, it is not likely to remain structurally capable for very long.

Impregnated or Pressure-Treated Application

The last, most prevalent treatment, is to use pressure-treated or impregnated fire-resistive treatments. These products use chemicals similar to the surface treatments, but the chemicals are forced through the surface into the wood fiber or impregnated during the manufacture of the product (such as might be found in a composite material). This is the most acceptable and widely-used approach to fire protection of wood members. Although the integrity of the fire protection can still be compromised by cutting or drilling, there is a sufficient amount of penetration depth into the material of the wood that it will remain fire resistive for the duration of its rated time even if the surface of the wood is compromised; instead of burning through a thin layer of surface treatment, a fire would have to burn through several millimeters of material before it reached anything that would easily burn or had not been reached by the chemical treatment.

Although these may seem like minor or unimportant differences, city inspectors and reviewers do not see it that way and may make you re-built non-compliant portions of your framing! Let EVstudio help you make the right decision with your project and ensure that you don’t have to fix errors due to the incorrect product being installed.