Resolving a Ground Loop Issue

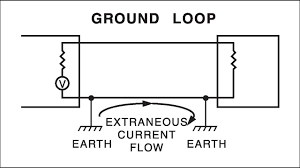

A ground loop occurs when interconnected electrical devices create multiple paths to ground, forming closed conductive loops. Recently, I encountered one for the first time in my career.

A client reported issues with two electrical services for a large multi-family complex. Both 2500A 208/120V 3PH 4W services repeatedly tripped their 2500A 3P electronic trip main circuit breakers. The ground fault sensors, factory set at 150A, detected faults, making it difficult to reset the breakers. Measurements revealed unusual current readings. Phase currents were low, around 300A per phase with minimal imbalance. However, the neutral carried 251A—high for a balanced 3-phase system. Furthermore, the equipment grounding conductor showed 67A of current flow, which should never occur under normal conditions.

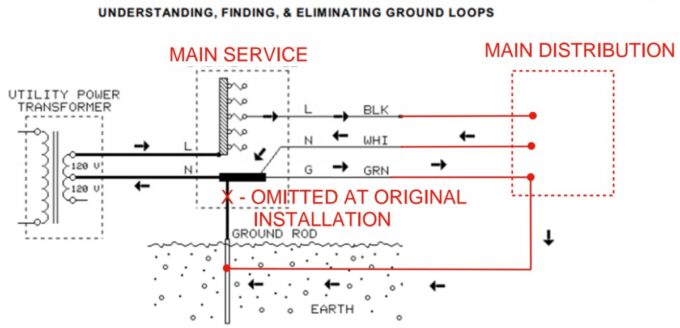

This issue stemmed from a ground loop caused by the absence of a proper Grounding Electrode System connection. A forensic evaluation revealed that the required Grounding Electrode Conductor, per NEC 250.64(D)(1), was missing. The service equipment enclosures lacked the necessary connection to the remote System Ground Bus in the main electrical room. Although the Ground Bus was correctly connected to the available grounding electrodes, the absence of a solid connection via the required 3/0 AWG copper conductor forced neutral current to flow through multiple equipment grounding conductors. This improper configuration created the ground loop path.

The problem persisted unnoticed for over a year because the facility “passed” inspection despite this major oversight. Reports indicated that some inspections were conducted from a “windshield” perspective during construction. While humorous in hindsight, this omission represents a serious failure across several levels of responsibility. National Electrical Code (NEC) Article 250, covering grounding and bonding, is the largest section of the code for good reason. Proper grounding and bonding are essential for safe electrical system operation.

Fortunately, fixing the issue was straightforward. The team retroactively installed the missing Grounding Electrode Conductor and connected it to all available electrodes per NEC 250.58 and 250.64(D). Once grounded and bonded correctly, all abnormal readings returned to normal, and current flow on the equipment grounding conductors ceased.

This experience serves as a critical reminder: thorough inspections and adherence to NEC requirements are vital. While mistakes happen on large projects, safety demands attention to every detail. Now that the system is functioning as intended, I can sleep peacefully again!