The Power of SKU Numbers in Lean Manufacturing and Offsite Construction

In modern manufacturing, precision, efficiency, and inventory control are essential. One of the key tools that supports all three is the SKU, or Stock Keeping Unit. While a simple concept, the SKU is a foundational element in managing production, supply chains, and inventory—especially in offsite construction, where component tracking and inventory accuracy are critical.

A Brief History of SKU Numbers

SKU systems originated in the mid-20th century as retailers and manufacturers sought better methods to track inventory. Before that, businesses used paper logs or manual systems that were prone to error. As computers and point-of-sale systems developed, SKU numbers became essential for categorizing products and tracking movement through a supply chain.

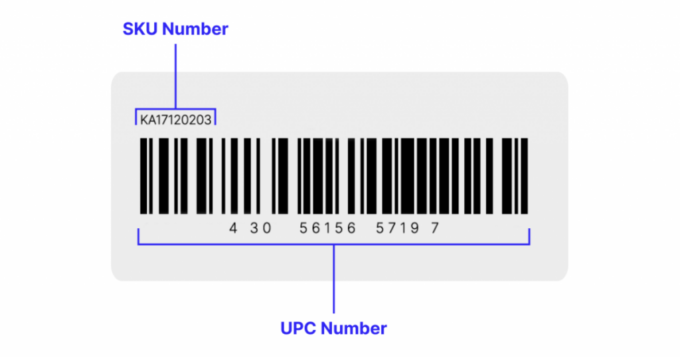

Unlike UPCs (Universal Product Codes), which are standardized globally, SKUs are internal codes created by businesses to suit their own categorization. A SKU can identify a product’s type, size, color, or other key features. It helps ensure each variation of a product is tracked individually.

How SKUs Work in Manufacturing and Inventory

In manufacturing, SKUs serve several purposes:

-

They represent individual parts or product variations.

-

They allow real-time inventory management.

-

They support procurement and restocking workflows.

-

They enable cost control and demand forecasting.

By assigning a unique SKU to each item, manufacturers gain clear visibility. A company can quickly identify low-stock items, excess materials, or production bottlenecks. This insight supports fast decision-making and responsive supply chains.

SKUs and Lean Manufacturing

Lean manufacturing focuses on minimizing waste and maximizing value. Managing SKU inventories effectively is a core Lean principle. Too many SKUs can create complexity, clutter warehouses, and increase costs. Too few can lead to material shortages and production delays.

Lean practices encourage teams to:

-

Standardize components across multiple products.

-

Reduce SKU proliferation by eliminating low-turnover items.

-

Use data to forecast demand and align inventory levels.

Efficient SKU management ensures manufacturers only produce and store what is needed. It supports just-in-time delivery, shorter production cycles, and greater agility.

SKU Management in Offsite Construction

In offsite construction, projects are built in controlled factory settings. Each component—from wall panels to bathroom pods—requires precise materials and specifications. SKU management is critical to tracking those components from design to assembly.

Offsite factories use SKU databases to:

-

Track inventory for framing, fasteners, finishes, and fixtures.

-

Coordinate procurement with supplier schedules.

-

Bundle components into project-specific kits.

With thousands of SKUs moving through the factory, errors or shortages can derail production. That’s why design teams must align closely with the factory’s supply chain and part library.

How EVstudio Aligns Design with SKU Systems

At EVstudio, we collaborate directly with offsite manufacturers. We ensure that the design documents reflect available SKUs and avoid unnecessary customization. Our architects and engineers:

-

Coordinate early with manufacturers to access their approved materials and parts list.

-

Incorporate SKU-specific components into the design set.

-

Adjust detailing and schedules to match available inventory and supply chain timing.

This alignment prevents rework, reduces change orders, and ensures a smoother production process. It also supports the factory’s Lean goals by avoiding non-standard components or parts outside the current catalog.

For example, instead of designing a custom plumbing assembly, we use existing assemblies in the manufacturer’s SKU database. That choice reduces lead times and simplifies installation. Similarly, we avoid specifying finishes or products not currently stocked by the factory, which helps control project cost and time.

The Bottom Line

SKU numbers are more than inventory tags—they are tools for planning, production, and precision. In offsite construction, managing SKUs effectively is crucial to maintaining efficiency, quality, and profitability. At EVstudio, we treat SKU coordination as part of the design process, not an afterthought.

This integration helps us deliver smarter designs that are buildable, efficient, and aligned with factory workflows.

Resources: