A deep foundation system that is gaining popularity in areas with difficult soil, contaminated soil and due to its speed of construction is steel screw piles.

At first glance screw piles look like the typical helical pier. However, there are significant differences that make a dramatic change in capacity. First, the screw piles are installed as a single continuous piece in lieu of sections bolted together. Second, the machinery used to install screw piles is larger and capable of producing a higher torque.

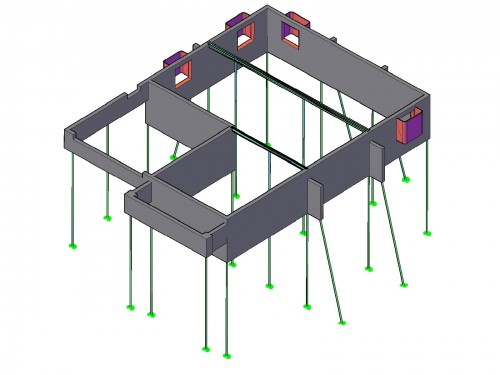

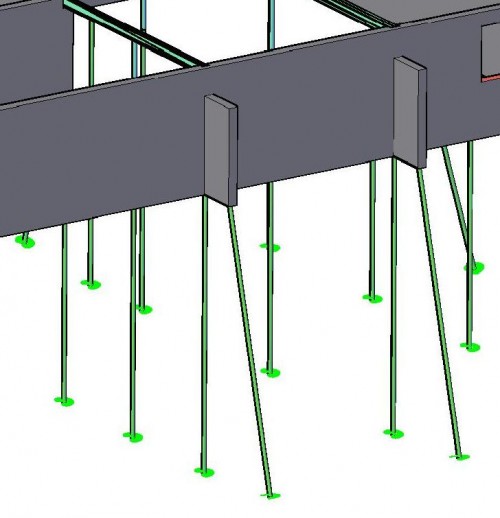

The components of a screw pile are simple; a steel shaft, steel helix at bottom of shaft, and a connection plate at the top of the shaft. Screw piles can vary in size to accommodate different design loads. The steel shaft size is a function of axial load, torsion during installation and thickness due to corrosion. The helix is a plate that is shaped just like the threads of a wood screw and engages the soil to distribute the axial load and it locks into place to provide tensile loads as well.

One of the first questions people have is, “How long will it last until failure from corrosion?” There are several factors that go into corrosion of steel; oxygen, moisture, dissolved salts and other corrosive chemicals. Since there is very little oxygen in the soil, corrosion is limited and can be controlled by using thicker material to allow for expected corrosion. The life of steel screw piles can be 50 years to an indefinite period depending on the type of structure and life span needed.

I designed foundations in Stapleton where the site was located over the old terminal and contaminated soil was discovered. If typical straight shaft drilled piers were used the spoils from drilling the hole would have had to been bagged and disposed of properly. To avoid bringing contaminated soil up to the surface steel screw piles were used.

I list a lot of PROS below and for good reason. I have been very impressed with screw piles and the wide range of uses of them. EVstudio was recently visited by Alpine Site Services for a lunch and learn. Mike Oliveira discussed how screw piles are installed and the many advantages to their system over other typical foundation types. What really impressed me was the speed of placement of screw piles. Alpine can place 30 to 50 screw piles in one day!

Another great advantage to screw piles is that they can be placed at an angle to provide bracing and tension resistance that is aligned with the force of the tension. An example is a typical counterfort that braces a foundation wall. You can see the angled screw pile above.

PROS

Fast Installation

Can be Proof Tested

Negligible Uplift Pressure from Swelling Soil

High Capacity up to 500kips

High Tensile Resistance

Made from a reusable material (LEED point)

CONS

Specialized System

Large Equipment

Concerns with Corrosion

2 thoughts on “Steel Screw Pile Foundation”

Thank you James,

What you briefly described sounds very similar to an elevated house commonly seen in flood zones, but I’m sure your intention is not to raise the house 8ft off the ground.

Using steel this can be achieved, the only issue you will run into would be the lateral capacity of the screw piles. But there are of course ways to bracing the structure or improve the lateral capacity of the piles.

I would be happy to meet with you to discuss your thoughts and see how we can help.

Greetings,

I am an Architect in Denver, and have often found myself reading your blogs, i.e. SIPS, ICF, and now Pile foundations. Trying to bring Green to small projects and keep them affordable has brought me to the Pile solution, but not due to bad soils, simply to not use concrete in my design and minimize excavation work ($). By “Floating” the house (800sf) off the ground, using a Post (Pile) and Beam (MTL Frame) foundation system I hope to bring some low cost affordable housing to those who most need it.

So, I am trying to understand if the design community has had any direct experience with a “Raised” house type of approach and how are colleagues at the City view this concept?

Thank you for your blog, the information is great.

James Oeinck

303-359-5325

Comments are closed.