There are many structural failures that can take place after a structure is in place. But is important to know what kind of failures can take place while you are designing a structure.

Some of the more common failures include:

- Failure of Connections

- Failure of Beams

- Failures in Tension and Compression

- Local Failures

Failures in connections usually happen when there is an unpredictable force. They are designed to take on secondary forces but there is always an unpredictable force. There can also be issues if the connections weren’t designed to have enough bolts or if the weld isn’t strong enough. A good connection and failed connection can be seen below.

Failures in beams happen when it fails in bending it can also fail due to torsional buckling. When the lateral loading on a beam increases beyond it’s limits it can cause too much bending and the beam will fail. Failure due to torsional buckling happens when the beam “twists”

Failure is compression is caused by the buckling of a member. If the member isn’t designed to take a large amount of load it will cause the member to buckle and ultimately fail.

Failure in tension occurs when a member is stretched beyond it’s limits. When a member fails in tension the member is usually yielded before the necking phase occurs. This kind of failure is rare if the structure is designed properly.

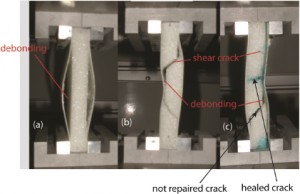

Lastly, local failures occur if your member is designed to be strong and can not fail on the “global” level. “Global” level failures are those that are discussed above. The most common local failure is the failure at the I Section which can be seen in the image below.Also a common local failure is when a beam buckles due to the pressure. The beam will not completely fail it will only buckle in a certain spot. This causes a reduced stiffness to the beam and can be seen below.