We recently talked about a variety of building methods. Within each method are different ways to build. Here we talk briefly about three wood framing methods.

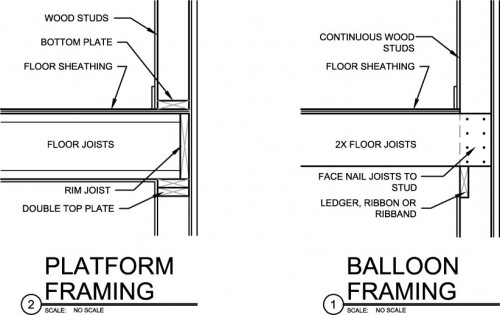

Balloon Framing –This method of framing was fairly popular on the east coast and parts of the Midwest in the past. Today it is not generally allowed by current building codes. However, it is good to be aware of the method in the event that it is encountered in the field.

In this type of framing the wall stud rests on the sill plate with a rim joist in the interior side and then the floor joist. The stud wall is continuous from the sill plate to the top plate. At the second level the floor connection, joists rest on a ledger and are then face nailed to the studs. Refer to drawing one (1) below.

Platform – This is the most common form of wood framing today. In this situation floor joists will rest on a sill plate or on top of a stud wall. The next level of wall framing will then sit on top of the fully sheathed floor joists. This method provides a built in fire stop and also creates a platform on which to construct the upper level wall. Balloon framing does neither of these. Refer to drawing two (2) below

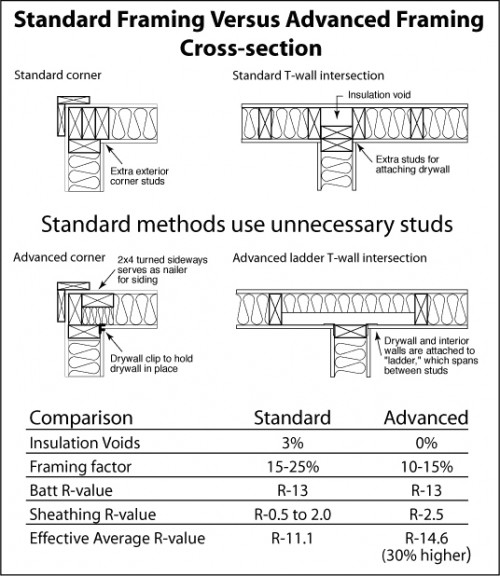

Advanced – This framing method, also known as Optimum Value Engineering (OVE), is a type of platform framing that makes better use of lumber. In addition more of the exterior wall can be insulated due to the more efficient framing. Some of the key aspects are:

- Advanced Corner Framing – Allows the use of one less stud in a corner and also provides space for more insulation to reduce thermal bridging.

- 24” Stud Spacing – The building is designed on a 24” module. This allows more insulation in the exterior walls, uses fewer studs and also lets the roof joists bear directly on each stud.

- Single Top Plate – Since the roof truss layout can be on the same 24” module as the wall studs they can stack directly on the studs which creates a direct path for roof loads to the foundation. Now the top plate acts to tie the stud wall together rather than also providing bearing capacity.

- Ladder Framing at T-wall Intersections – Ladder framing reduces thermal bridging and also utilizes the small amount of scrap wood that is left from advanced framing techniques.

- Roof Pitch Adjustment – In structures that have simple roofs it is easy to adjust the pitch to a non-standard pitch that allows for better utilization of roof sheathing. The pitch can be adjusted so that full and half sheets of sheathing can be used and as a result, reduce waste and labor.

- Materials, Labor and Heating/Cooling Reductions – When properly implemented advanced framing can reduce materials costs, labor costs and save on heating/cooling bills. This adds up and can easily reduce the cost to build or provide room in the budget for some upgraded fixtures or finishes.

The good news for advanced framing is that it is getting easier with the advent of Building Information Modeling (BIM) software. As with all building decisions, if the framing type is discussed early on, it is extremely simple to implement during the design phase of the project. The following graphic is supplemental to the advanced framing discussion and was produced by www.energysavers.gov.