Unlocking Wood Strength: How Load Duration Factors Boost Fastener Capacity

Have you ever wondered how much stronger a fastener becomes when subjected to short-term loads like wind or earthquakes? While browsing the Simpson fasteners catalog, I came across an intriguing statement: “Allowable loads are shown at the wood load duration factor of CD = 1.00. Loads may be increased for load duration by the building code up to a CD = 1.60.” Consequently, this raises a fascinating question—does a load duration factor of 1.6 really mean that the fastener’s capacity increases by 1.6 times?

Curious about whether this was truly the case, I decided to take a deep dive into the National Design Specification (NDS) to understand how various factors, especially load duration, influence the adjusted design values for wood structures. What I found highlights just how crucial these adjustments are in creating safe, efficient designs.

Key Adjustment Factors for Sawn Lumber

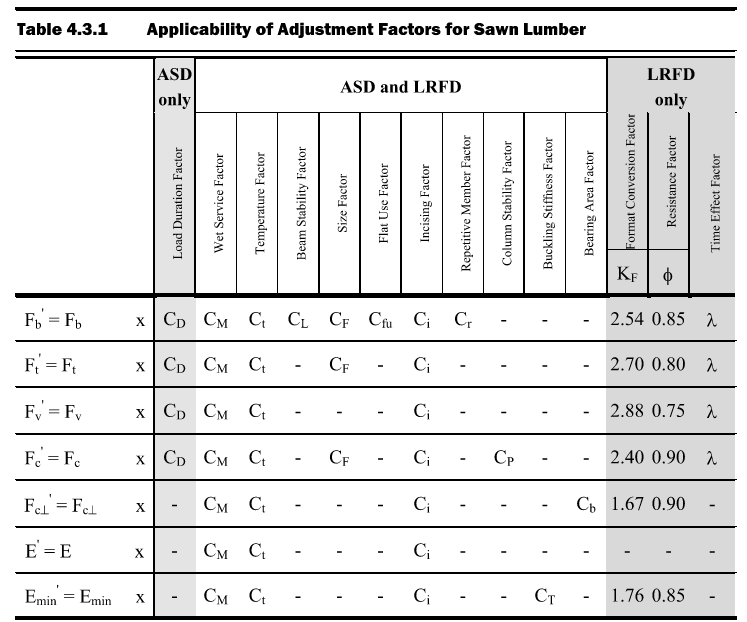

For sawn lumber, the National Design Specification (NDS) lists several applicable adjustment factors:

- Load Duration Factor (CD): Adjusts for the duration of applied loads.

- Wet Service Factor (CM): Adjusts for prolonged exposure to moisture.

- Size Factor (CF): Accounts for variations in member size.

- Temperature Factor (Ct): Adjusts for elevated temperatures.

- Repetitive Member Factor (Cr): Applies when multiple members share a load.

- Beam Stability Factor (CL): Applies to bending members.

- Column Stability Factor (CP): Applies to compression members.

- Flat Use Factor (Cfu): Applies when sawn lumber is used flatwise.

- Incising Factor (Ci): Applies to sawn lumber that has been incised for preservative treatment.

All these factors are applied multiplicatively to determine the final adjusted design value. For a comprehensive list of which adjustment factors apply under Allowable Stress Design (ASD) and Load and Resistance Factor Design (LRFD) methods, please refer to Table 4.3.1.

(Reference: National Design Specification for Wood Construction, 2018 Edition)

Detailed Explanation of Load Duration Factor (CD)

Wood exhibits different strength properties depending on how long a load is applied. The load duration factor accounts for this behavior, increasing design values for short-term loads and decreasing them for long-term or permanent loads. Table 2.3.2 of the NDS provides commonly used load duration factors:

| Load Type | Duration | CD |

| Permanent | 10 years or more | 0.9 |

| Normal | 10 years | 1.0 |

| Snow | 2 months | 1.15 |

| Construction | 7 days | 1.25 |

| Wind or Earthquake | 10 minutes | 1.6 |

| Impact | Instantaneous | 2.0 |

- Application: The shortest duration load in a combination governs the design. For example, if both permanent and wind loads are considered, the factor for wind (1.6) would apply.

Example Calculation: Adjusted Design Value for HEM Fir #2 Stud in a Load-Bearing Wall (ASD Method)

Normal Load

- Reference Compression Parallel to Grain (Fc): 1,150 psi

- Load Duration Factor (CD): 1.0 (normal load)

- Wet Service Factor (CM): 0.75 (high moisture)

- Size Factor (CF): 1.0 (standard stud size)

Applying the adjustment factors:

The adjusted compression design value is 863 psi.

Wind Load

- Reference Compression Parallel to Grain (Fc): 1,150 psi

- Load Duration Factor (CD): 1.6 (wind load)

- Wet Service Factor (CM): 0.75

- Size Factor (CF): 1.0

Applying the adjustment factors:

The adjusted compression design value is 1,380 psi.

Key Difference: The higher load duration factor for wind (1.6) compared to normal load (1.0) results in a significantly higher adjusted design value.

Summary

This analysis began with a simple question: does increasing the load duration factor (CD) directly increase the capacity of a fastener by the same ratio? The answer is yes, increasing the factor to 1.6 allows for a 1.6 times increase in allowable load capacity. Through example calculations and a deeper understanding of the NDS guidelines, it is clear that load duration factors can significantly impact the final design values. However, it’s essential to remember that while higher CD values allow for increased design loads, other factors like moisture conditions and member size also play critical roles. Therefore, understanding how to correctly apply these factors ensures safe and efficient wood construction. Contact our Structural Engineering experts at EVstudio to see how this can apply to your project.

(Reference: National Design Specification for Wood Construction, 2018 Edition)