Navigating Building Codes for Roof Assemblies

Introduction

Understanding building codes can feel overwhelming, with multiple sections leading to various requirements that need verification. Overlapping regulations can create different interpretations, making it essential to consult the local building authority for compliance. Navigating Building Codes for Roof Assemblies is challenging, but we’re here to help!

The International Code Council (ICC) outlines vented and unvented roof assembly requirements in the International Building Code (IBC) for commercial structures and the International Residential Code (IRC) for single-family homes. The International Energy Conservation Code (IECC) mandates minimum insulation R-values based on climate zones. These codes focus on moisture control, ventilation, and thermal envelope integrity for truss attics and rafter-framed roofs. This article primarily discusses unvented roof provisions from the IRC 2021.

History and Terminology

Code Evolution

Unvented attic assemblies gained traction in warmer climates during the 1990s, leading to moisture and mold concerns. The Department of Energy’s Building America Program, led by Joseph Lstiburek, introduced research that informed the 2024 ICC code updates. The new code clarifies insulation use in vented and unvented attics and rafter cavities.

Materials

Historically, air-permeable insulation dominated walls and roofs, making ventilated roofs common. In recent decades, air-impermeable insulation has become widely used. Air-permeable insulation, like fiberglass batt, cellulose, and mineral wool, allows airflow and moisture transfer. Air-impermeable insulation, including rigid foam board and spray foam, acts as a barrier against air and moisture.

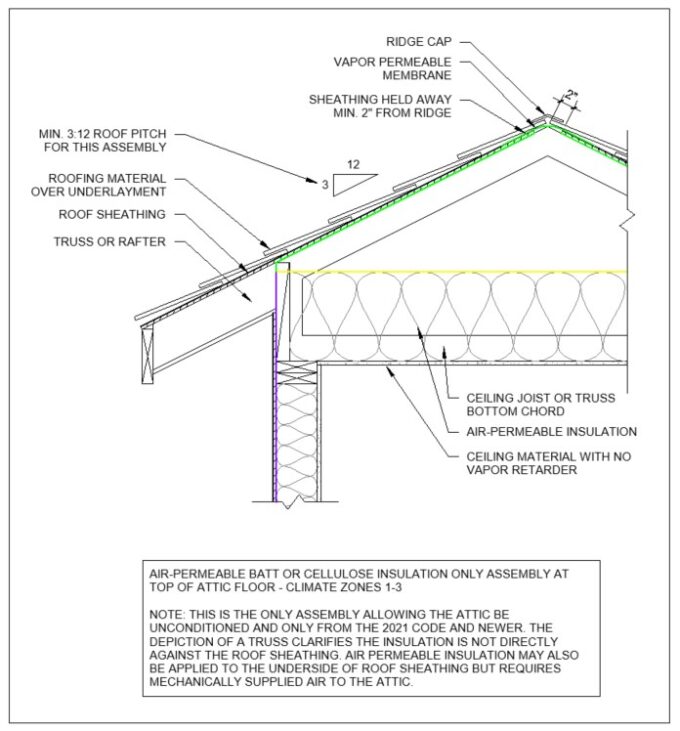

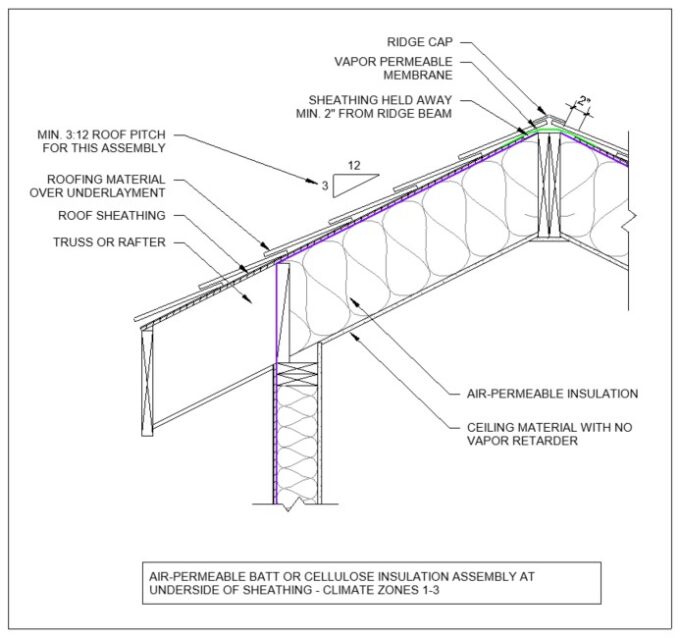

The code now allows vapor diffusion ports in climate zones 1-3, enabling air-permeable insulation use in unvented attics while maintaining an unconditioned attic space. Vapor diffusion ports at ridges, hips, and high roof slopes release water vapor without permitting airflow. The code distinguishes vapor retarders and vapor-permeable membranes, both limiting moisture transmission, from roof underlayments that shed water.

Control Layers

For a building to perform efficiently, it must regulate water, air, vapor, and thermal movement. The 2018 IRC introduced Section R806.5 to address these control layers, ensuring better performance. Roof-wall connections are critical in unvented roof assemblies.

Roof Ventilation

Vented Roof Assemblies

Vented roofs help maintain a temperature close to outdoor conditions. In cold climates, they reduce ice damming risks, while in warm climates, they minimize interior condensation. The thermal envelope and vapor barrier at the ceiling reduce energy costs. However, vented roofs require careful venting design at overhangs, ridges, and gables to prevent moisture intrusion. In wildfire-prone areas, vented attics pose a fire risk due to ember infiltration. High-humidity coastal regions may also require additional moisture mitigation strategies.

Unvented Roof Assemblies

Unvented roofs offer advantages in wildfire-prone and coastal areas, improving building longevity and safety. Positioning the air and vapor barrier at the roof deck creates an airtight enclosure. In low-slope roofs, designs without overhangs, or buildings with extensive rafter framing, unvented assemblies are often preferable. However, insulation placement on or beneath the roof sheathing conditions the attic, potentially increasing energy demands. Large trussed attics may not benefit from unvented designs due to increased conditioned space requirements.

Application of IRC Code Section R806.5

IRC Section R806.5 governs unvented attic and rafter assemblies, permitting unvented roofs in all climate zones using air-permeable or air-impermeable insulation. Subsection 5.2 mandates vapor diffusion ports and a vapor-permeable membrane in climate zones 1-3 when using air-permeable insulation. Additionally, mechanically supplied attic air is required when the occupiable space is conditioned, with new exceptions in the IRC 2021 update.

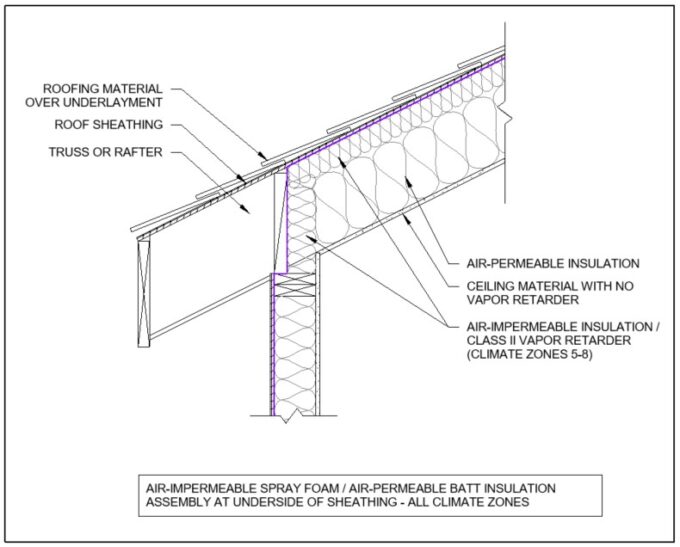

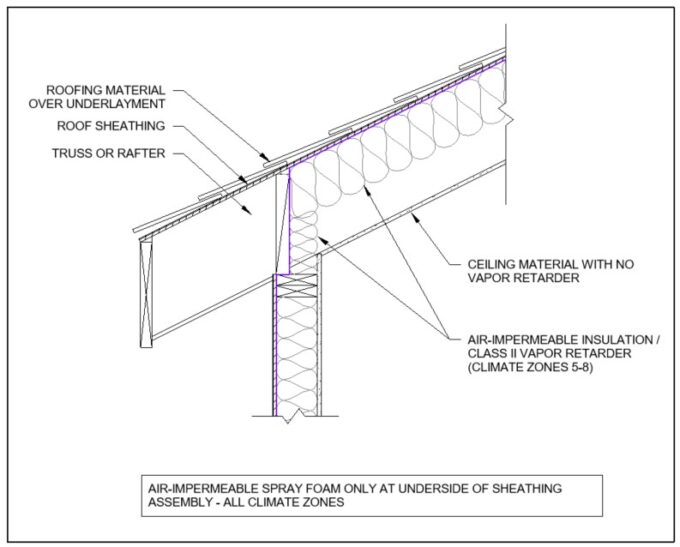

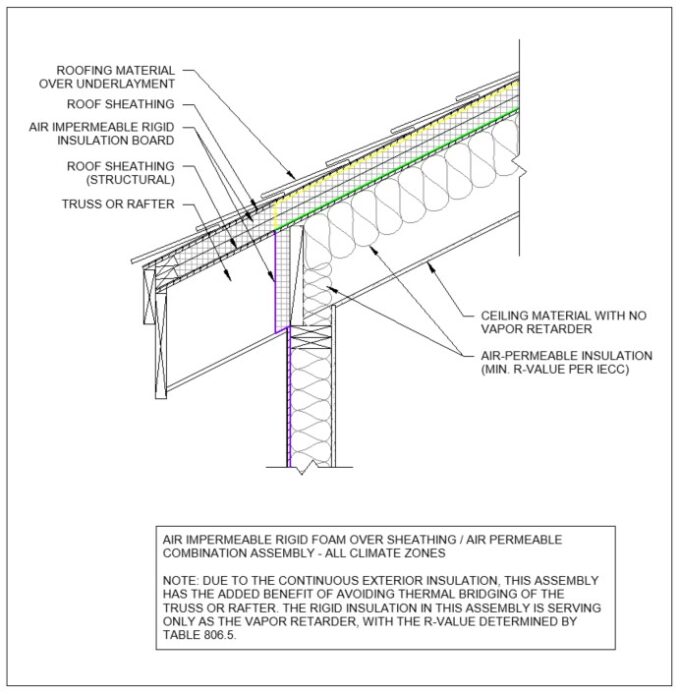

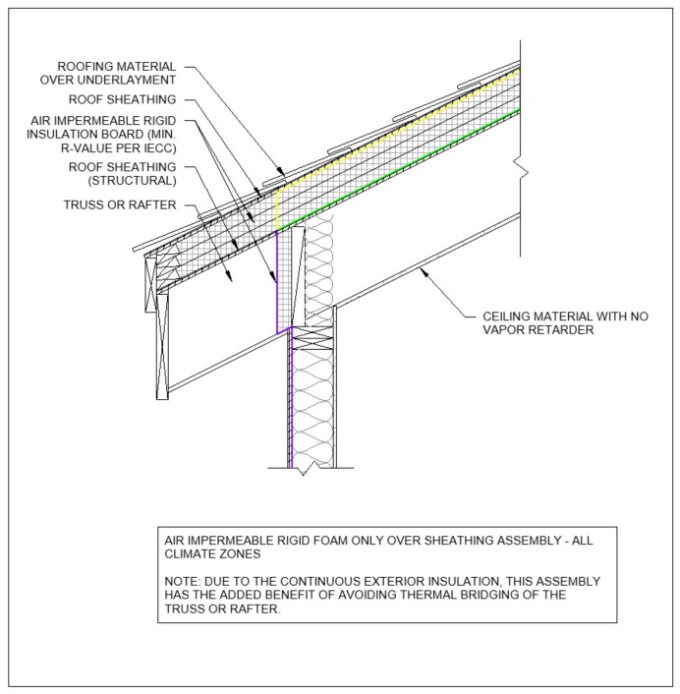

Subsection 5.2.8 introduces a provision allowing insulation placement atop the attic floor and ceiling. Climate zones 5-8 require air-impermeable insulation to function as a Class II vapor retarder or be coated accordingly. Table R806.5 specifies minimum R-values for condensation control when air-permeable insulation is applied against roof sheathing. These values ensure vapor control but do not replace the thermal requirements outlined in the IECC. Wood shake shingle roofs still require a ¼-inch air gap above the sheathing.

The following details illustrate compliance strategies for various assemblies, emphasizing control layers. The water control layer is omitted for clarity, focusing instead on air, vapor, and thermal layers. Wall cavities assume closed-cell spray foam use to achieve air, vapor, and thermal control with a single material. For additional assistance, reach out to our team of experts at EVstudio.

Control Layer Key:

Purple Line = air, vapor and thermal.

Green Line = air and vapor.

Yellow Line = thermal only.

References:

Controlling Moisture in Unvented Attics – Code Compliance Brief | Building America Solution Center

RR-0108: Unvented Roof Systems | buildingscience.com

Vapor Barriers or Vapor Retarders | Department of Energy

The Four Control Layers In A Building Envelope | LogixBrands.com | Engineered Insulation Products