Do-it-yourself projects are always going viral online, and not always for the right reasons. When it comes to home improvement, especially something as tricky as a floating stair, bad DIY is knowing what the shape is supposed to look like, but not understanding the materials, structure, and physics of what goes beneath it. (Some things truly are best left up to professionals!) While botching a DIY haircut is something that might feel like the end of the world when it happens, your hair will (probably) grow back.

Relying on this DIY floating stair could land you in the hospital:

Engineering Red Flags

That’s also why the biggest red flag revolves around the engineering (or lack thereof) for what’s know as the “moment arm.” A moment arm is calculated simply as force multiplied by the distance from the base. In the case of a stair like this, that means that there is a rotational force at the wall that is fairly significant. Safe construction would not be achieved without engineering anchors and support at the wall.

Even if the brackets used in a DIY like this are strong enough to hold up the weight of a person, and the fasteners are made of a material that will not shear (rip in half from lateral force), a stair made of so many small parts will flex and move every time a person walks up them. This allows the fasteners to pull ever-so-slightly out of the wood, allowing a bit more motion and pulling a bit further out each time. (Think of pulling a tent stake out of the ground: kind of hard pulling straight up, but if you wiggle it side to side to widen the hole, then it comes out pretty easily.) In short order the whole system would pull apart.

What makes a good floating stair?

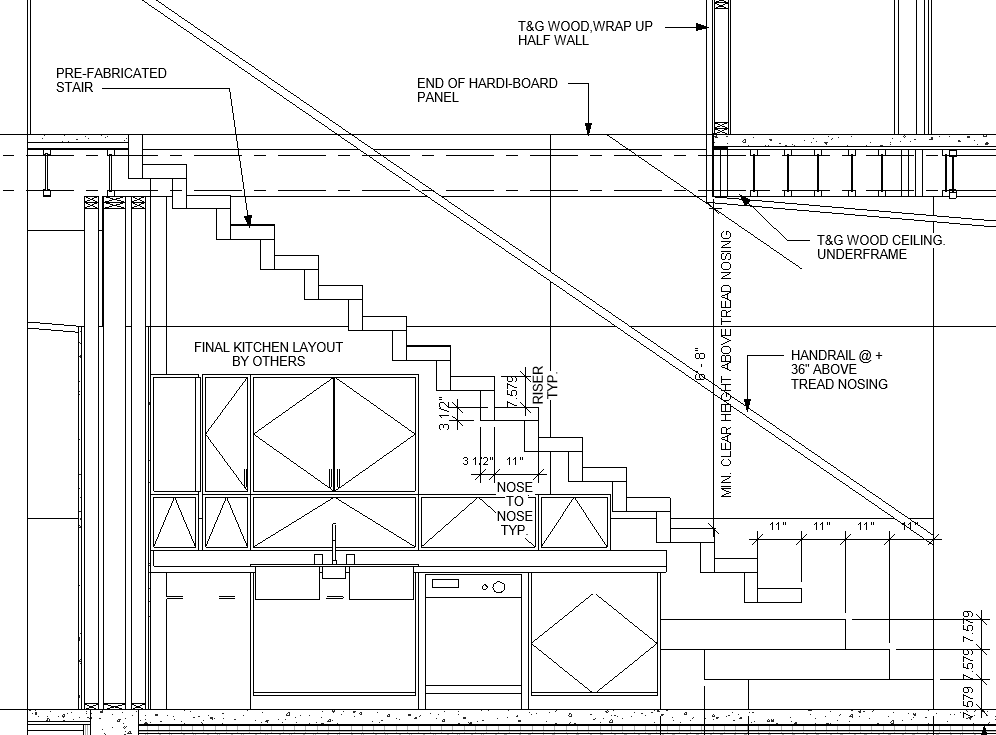

EVstudio has designed homes with floating stairs, including engineering the surrounding structure to safely support a pre-fabricated floating stair. An example is shown here:

As designers of our built environment, we are always looking to advance and progress how things are constructed. That can entail looking at alternative materials and how they can be put together. While I applaud the creativity in theory, the original image I found is an example taken to a different and unsafe level. Staircases can be a great opportunity to do something unconventional and show off your unique tastes in style and aesthetics, whether you’re a design professional hired by a home owner or a DIY-er. Staircases entail numerous safety concerns, so it’s always best to consult a design professional before taking on your DIY stair project.

Do you have a unique design idea? Let us know. EVstudio would be glad to assist you in your vision – safely!