At this point, I think it’s fair to say that I’m a proponent of post-tensioned structures. I’ve found that they can be very economical, and there are many things you can only do with post-tensioned concrete. However, there’s one point that I think all structural engineers agree on: while post-tensioning is a great tool to have available, reviewing the elongation reports is a pain. So: what is an elongation report, and why are they important?

As anyone familiar with my post-tension elevator speech will know, the key element of post-tensioning is pulling on the tendons. ACI 318-11 section 18.20.1 states:

Prestressing force shall be determined by both of (a) and (b):

(a) Measurement of steel elongation. Required elongation shall be determined from average load-elongation curves for the prestressing steel used;

(b) Observation of jacking force on a calibrated gage or load cell or by use of a calibrated dynamometer.

Cause of any difference in force determination between (a) and (b) that exceeds . . . 7 percent for post-tension construction shall be ascertained and corrected.

What does that mean? Post-tension tendons are stressed using a hydraulic ram, which is connected to a gauge. That gauge is calibrated by the jack supplier (usually the post-tension material supplier) so that the operator knows exactly what pressure corresponds to 33.0 kips (80% of the minimum ultimate tensile strength of the tendon). Most suppliers put a stripe on the dial, so the operator only needs to observe the needle hit the stripe to know that the tendon is stressed correctly. Once the tendon has reached the correct gauge pressure, the operator reverses the pump, seating the wedges in the anchor, and releases the tendon.

But what about “. . . required elongation shall be determine from average load-elongation curves for prestressing steel . . .“? That’s a good question, and the answer is somewhat in-depth.

Every post-tension project has a list of elongations. For a slab-on-grade job, this can be as simple as a spreadsheet that takes tendon slab length and multiplies it by 0.08; for an elevated deck project, every tendon has a listed elongation which is calculated by the detailer and approved by the engineer. At their most basic, it’s possible to estimate the elongation of a tendon using the formula Δ = PL/AE. That is, the elongation (Δ) is equal to the product of the force (P) and the tendon length (L), divided by the area of the strand (A) and the tendon modulus of elasticity (E). Without going into too much detail, every batch of strand has a slightly different “E” value; steel mills chop off a length from each batch and check this value before they ship the strand to fabricators.

This would seem to indicate that every tendon of a specified length has the same elongation. While this is true in theory — and works well enough for slab-on-grade applications — there are four factors that complicate the calculation.

- Coefficient of Angular Friction. As tendons curve, the steel strand — which is fairly stiff — moves around in the grease. While a properly-placed tendon will never have kinks or other sharp bends, this movement does increase the amount of effort required to stretch the tendon. Depending on the fabrication process, the diameter of the tendon, and the post-tension coating used, this coefficient — and the effort required — can vary. Material suppliers watch their elongation reports carefully and adjust this value as they see fit.

- Tendon Drape. The primary source of tendon curve is the profile specified by the engineer of record. Each span has a listed high and low point designed to balance dead loads. Typically, the deeper the member, the higher the losses. A 36″ deep beam and a 10″ deep slab shouldn’t have exactly the same elongation.

- Tendon Wobble. In addition to the specified drape, it’s impossible to keep the tendons perfectly straight. Additionally, slight deviations around openings (like plumbing) is normal. “Typical” wobble values are rolled into what’s called a “wobble coefficient”, an average deviation measured per foot of tendon. Suppliers monitor this number as well, making sure that actual tendon placement is staying within the parameters they assumed.

- Anchor Set. When the pump reverses, two things happen: the tendon starts to slide back into the concrete, and the ram deploys a tool called the seating plunger. Both of these force a pair of steel wedges into the anchor cavity, and teeth machined into the wedges clamp onto the strand. However, how quickly this happens is a function of the ram and the tendon’s overall length (shorter tendons are “snappier”). Suppliers monitor this value as well — usually, it’s 1/4″, but for a very short tendon, it might go as high as 3/8″.

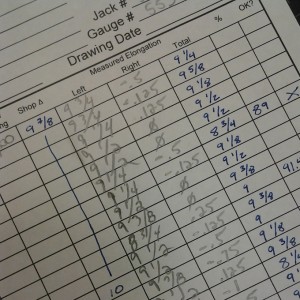

Every source of friction reduces the “P” in the elongation equation. The anchor set is taken straight off the top of the final Δ. Once the tendons have all been stressed, the installer (or inspector) measures how much the tendon stretched with a tape measure. These numbers are recorded and reported to the engineer.

Which brings us to the last line in Section 18.20.1. In general, the vast majority of tendon elongations fall within the 7% tolerance, with only occasional “long” or “short” pulls. It’s easy to ask that the installer re-pull the short tendons to ensure that the ram wasn’t reversed early, or the wedges didn’t slip unduly. When several tendons fall short of the specification, it’s necessary to review the calculations, re-pull a handful of tendons, confirm them with the revised calculations, and re-stress the remainder. Unfortunately, it’s only possible to safely re-stress a tendon once — so any issues with procedure, wedge quality or site conditions needs to be addressed immediately.

Once the revised elongation report is complete, the engineer may have to additionally re-evaluate his calculations to reflect that there simply isn’t as much compression or balanced load in the slab as he designed. This usually comes out to be only a couple of percentage points, but must be checked on a case-by-case basis . . . and can be a real nail-biter if the deck was just barely working to begin with, especially because the reinforcing steel is all in place.

Of course, EVstudio has the expertise you need to carry a post-tension project from start to finish. Our long history of elevated post-tension decks helps us evaluate the supplier’s calculations before tendons are shipped . . . and head elongation issues off while they’re still problems on paper, rather than cast in concrete.