As a member of the structural team here at EVstudio, I have found it extremely helpful to intimately know the construction tools used out in the field. I hope you find these details as important in your use, as I do for my designs.

Roof Sheathing Ring Shank Nails (RSRS Nails)

After their addition to ASTM F1667 Standard Specification for Driven Fasteners: Nails, Spikes, and Staples[i], Roof Sheathing Ring Shank Nails have been added to the 2018 NDS[ii]. They have been included as an accepted dowell-type fastener in Chapter 12 of the Standard and feature an increased withdrawal strength over smooth shank nails.

What are Roof Sheathing Ring Shank Nails?

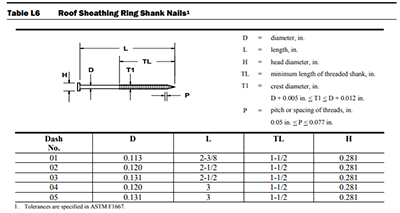

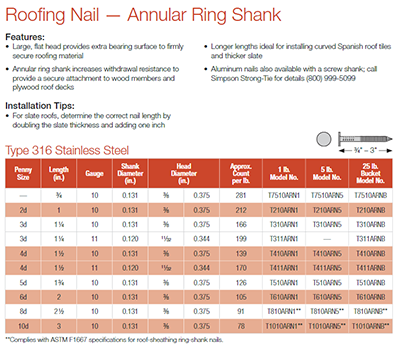

Roof Sheathing Ring Shank Nails are a dowell type fastener providing a higher withdrawal strength than a comparable smooth shank nail. They typically include a larger head than a smooth shank nail as well to provide extra fastener head pull-through strength. The figure below shows Simpson Strong-Tie’s Annular Ring Shank Roofing Nail. They are available in stainless steel and copper options.

Why do we need them?

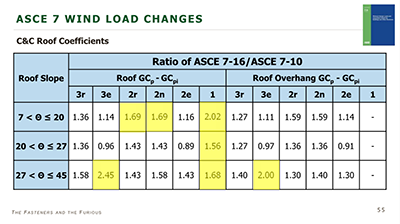

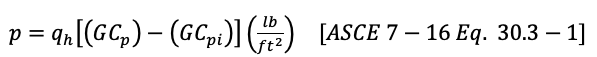

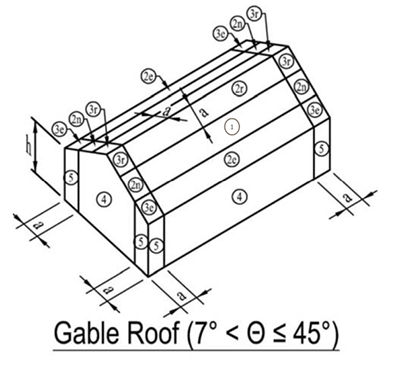

The acceptance of Roof Sheathing Ring Shank Nails comes after changes to ASCE-7’s wind load provisions. ASCE-7 16 includes significant increases in component and cladding wind pressure coefficients for roof zones[i]. Some wind pressure coefficients have even doubled in some roof regions. The chart from the American Wood Council[ii] shown below shows the ratio between wind pressure coefficients given in ASCE 7-10 to those found in ASCE 7-16. Wind pressure coefficients have mostly been increased with only a few zones showing a decrease.

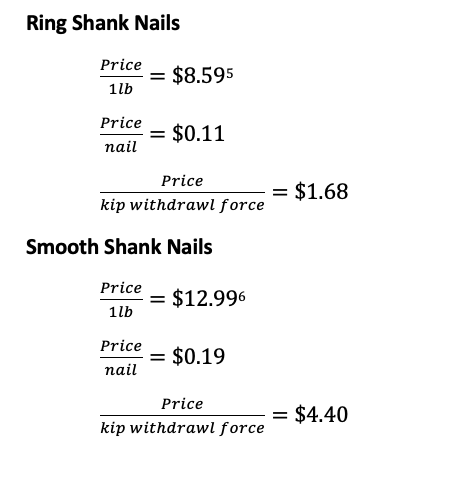

These higher uplift values create a demand for more uplift resistance. Simply increasing the amount of roof sheathing nails with a smooth shank is an option, but costs may be decreased by using RSRS nails with more withdrawal strength.

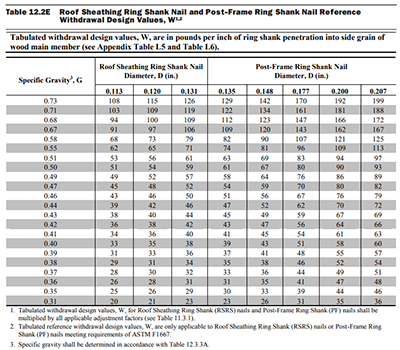

How is uplift capacity calculated for RSRS nails?

Capacity is calculated in a similar method to smooth shank nails. Guidance is provided by NDS section 12.2.3.2.

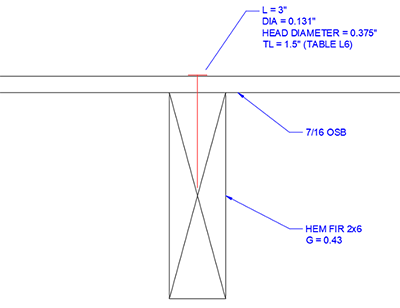

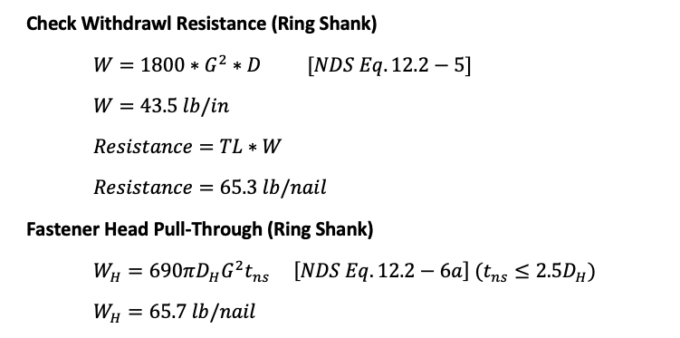

Example: Use Section 12.2 of the 2018 NDS to calculate the total uplift capacity of the following connection. Assume a stainless steel nail. TL values can be found in NDS Table L6 which gives typical dimensions for

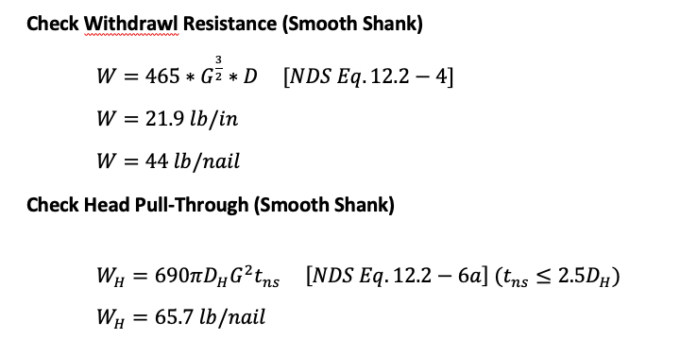

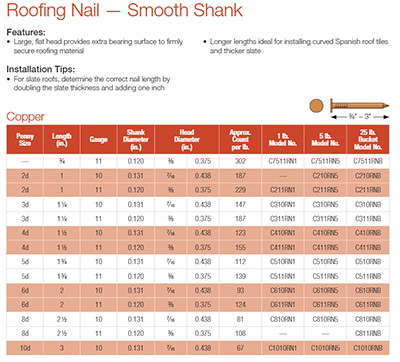

After calculating W and WH, it is found that withdrawal resistance controls with 65.3 lb per fastener. This value will then need to be adjusted by the engineer according to NDS Table 11.3.1 to find the adjusted withdrawal value of W’. Now compare this to the values of a smooth shank roofing nail of similar size. Simpson’s smooth shank roofing nails are available in copper.

Again, withdrawal resistance controls with a lower value of 44 lb/nail. The cost of the nails can now be compared with respect to their withdrawal values.

[1] ASTM F1667-18a, Standard Specification for Driven Fasteners: Nails, Spikes, and Staples, ASTM International, West Conshohocken, PA, 2018, www.astm.org

[2] 2018 National design specification for wood construction. (2018). American Wood Council, Leesburg, VA.

[3] Showalter, and Bradford Douglas. (n.d.). “Changes to the 2018 National Design Specification (NDS) for Wood Construction.” STRUCTURE magazine, <https://www.structuremag.org/?p=12746> (Nov. 4, 2019)

[4] Koch, L., and Kam-Biron, M. (n.d.). “American Wood Council Webinar.”