Windows are an important architectural component for both residential and commercial buildings and can significantly impact both construction budgets as well as energy use. According to consumer reports, the cost to replace the windows in the average house costs between $7,000 and $20,000.

Windows come in a variety of shapes and sizes. For the sake of this article, we will focus on the windows most commonly found in the United States:

Fixed – This window type consists of glazing that is non-operable (meaning it cannot be opened). Fixed windows are commonly used for large picture windows and also for windows that are a non-traditional (anything other than rectangular) shape.

Casement – Casement windows have a sash that swings out on a hinge and are usually operated with a mechanical crank arm at the base or side of the window. They are generally the most expensive option for window operation as they usually have many intricate mechanical parts. In some cases, a casement window may be hinged but not have a crank arm and would have to be fixed into an open or closed position manually. Casement windows are becoming increasingly dominant. Casement windows commonly are hinged on the left or right portions of the frame, but can also be hinged at the top (awning style window) or hinged at the bottom (hopper or bin-style window).

Single Hung – This type of window usually consists of two sashes where the top sash is typically fixed (meaning it cannot be moved or operated), and the bottom sash slides vertically to open or close the window.

Double Hung – A double hung window has two sashes and both sashes can be operated. Typically, the sashes can be removed from the window frame for cleaning.

Slider – Slider style windows operate similarly to the single and double hung windows, but move horizontally. They are typically slightly cheaper because they lack the counterweight systems that are required to balance the weight of their vertically-operating cousins.

Window frames and sashes are manufactured from a variety of materials but the most common are wood, vinyl, and aluminum. Higher-end residential windows typically use wood frames with some form of exterior cladding to protect the wood against weathering. In commercial settings, aluminum windows are almost exclusively used. Vinyl or fiberglass windows are almost always the least expensive option, but cannot be painted and often warp or fade with time. Wood frames are inherently insulated, but all other types usually require some form of insulation or a thermal break to limit the loss of heat through the frame.

Getting into some more terminology, “glazing” is the technical term for the type glass that is placed into a window and a “pane” is the actual sheet of glass. Most modern windows are double or triple-paned to aid with insulation. There are practically limitless combinations of glazing and treatments that can be applied to windows. The most common options for residential glazing are to select Low-E (low emissivity) glass which boosts the ability of the window to block solar radiation, and then to select a low Iron glass which will make the window appear “clearer” than standard glass which commonly has a green tint.

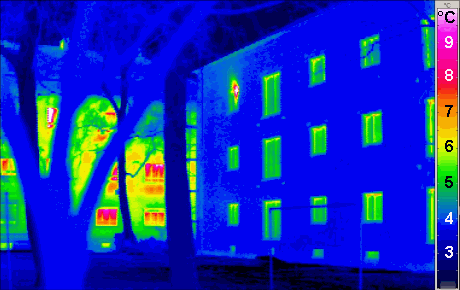

Windows can be one of the highest sources of heat loss in a building and so it is important to take some time to choose a window that is right for your project and energy considerations. The image below was taken using an infrared or thermal imaging camera which takes a “picture” of the surface temperature of objects. The building in the background is older and the red that you see corresponds to windows that are poorly insulated and leading to a high temperature difference in the image (roughly 10°F higher than the surrounding temperature). By comparison, the windows on the building in the foreground (green) are roughly 3°F higher than their surroundings. I’ll be writing another post soon about thermal imaging and how it can be used for investigating sources of energy loss or inefficiency in buildings if you would like to learn more.

Believe it or not, the non-moving air between panes of glass acts as a pretty decent insulator, but many windows now come with argon, krypton, or another inert gas filling to increase the insulation values of the window. If you are considering installing gas-filled windows in a high-altitude location (generally above 5,000 feet), verify with the manufacturer that the windows are rated for that altitude (along with the highest elevation they will have to be transported over) as the gas filling is usually sealed in at the factory and can either blow out the window seals or cause the panes to bow out at altitude.

Often it is a good idea to involve an architect and engineer when selecting windows and treatments as they can help you navigate the wide variety of options and energy considerations. In some locations, you may be eligible for a tax credit based on your window selection.

More technical information about windows can be found in the following EVstudio posts:

Technical Terms: https://evstudio.com/terms-to-know-when-choosing-windows-u-factor-shgc-vlt/

Egress Windows and Operation: https://evstudio.com/common-egress-window-sizes-and-operation/