Using pre-engineered roof trusses is one of the most common ways to construct a roof in residential construction. They are designed by roof truss manufacturers based on the information obtained from architectural and structural plans. Since they are designed by other engineers, it is fundamental for the project’s structural engineer to review the truss shops. Any issues found during the truss shop review process can be coordinated early before running into issues in the field. In this article you will explore the review process that a Structural Engineer goes through with truss shops in order to eliminate any potential issues that can arise during construction, creating a smoother process for everyone involved with the framing stage.

What are Truss Shops?

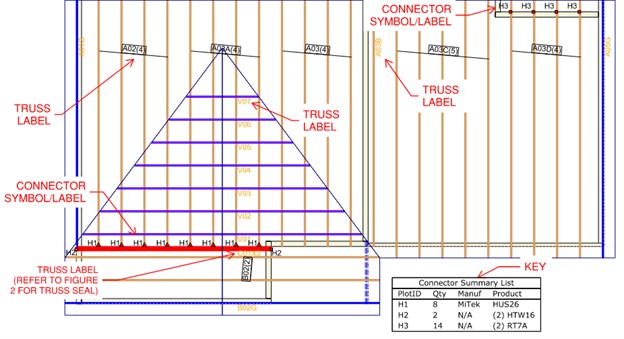

Truss shops are composed of two documents. First, the truss layout (Figure 1) depicts the arrangement of each truss in a plan view. Each truss is labeled along with any hardware used for attaching the trusses to the structure. Most truss manufacturers have a symbol in their layout located at each connection and a connector summary, or a key, where each connector is described.

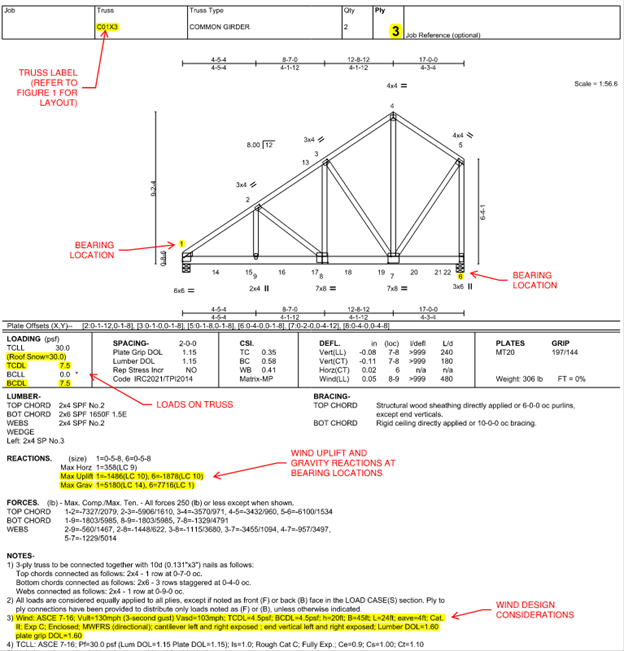

Second, the truss seals (Figure 2) illustrate each individual truss along with their design considerations. The truss drawing shows exactly how each truss will be constructed and the information that follows explains the wood species that will be used, the loads that were used to design them, the loads generated once the truss is loaded, and all the applicable codes that were used in the design process along with other information. What connects these two documents together are the truss labels. First you must look at the truss layout to identify a truss you would like to review, and then you can search for the truss in the truss seals.

What do Structural Engineers look for in a truss shop review?

The first thing that is reviewed are the loads and design codes. If the snow load, dead load, wind load, and design codes are correct, then it is safe to move on to the next step. If there are any incorrect design codes or loads, contact the truss manufacturer before moving onto the next steps as this can affect the loads computed. Next, the layout must be compared to the layout drawn in the structural roof framing plan. The layout of the trusses on the roof framing plan must match the layout of the truss shops.

The third step is to then individually check each truss. In particular, girder trusses are important to look at. A girder truss can be identified on the layout if it is supporting other trusses, and or is more than one ply. A girder truss can be looked at as a truss acting as a beam for other trusses to bear on. Since girder trusses support other trusses, their reactions on the bearing walls are higher than other trusses. That is why an engineer should verify that the bearing locations do not have an excessive gravity load, and if they do one of three solutions can be used; a bearing scab, interrupt the top plate, or install a truss bearing enhancer.

Verifying the uplift is also a big thing to look at. Other things to look at are to verify the number of plies, the bearing locations, and double-checking design parameters. Each truss should be reviewed for the same details. This is a general process that EVstudio uses to review truss shops and can vary by other engineers.

Why should Truss Shops be reviewed?

EVstudio’s structural teams are well-versed in reviewing truss shop drawings from many truss manufacturers. The benefits of having your structural engineer (and architect!) review the truss shop drawings before the trusses are manufactured cannot be overstated and can save the contractor and design team a lot of headaches later on down the road. For example, sometimes the layout on the roof framing plan does not match the layout created by the truss manufacturer. This can create issues if the loads that the structural engineer anticipated for are modified when the truss manufacturer alters the layout. For example, a girder truss might have shifted locations, creating an unanticipated point load on a header leading to a header that no longer is up to code. Or the reaction on a girder truss can be higher than the allowable bearing reaction, causing the girder truss to crush the top plates. The truss seals can also have incorrect snow loads, dead loads, wind loads, or design codes, causing the roof trusses to not be up to code.

Sending your truss shops to your structural engineer can save you a headache down the road. Yes, it’s an extra step, but preparing before construction starts by doing a truss shop review can save the project money and time. For your next project, work with a firm that will always advocate for your project to be done right, from the start. EVstudio’s architects and structural engineers are happy to work with your truss designer early in the design of your dream project to help make building department plan reviews quick and construction a little more painless. Let EVstudio know how we can help!